Lean tools to better serve you.

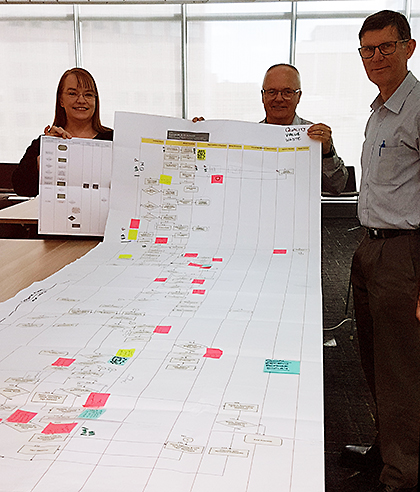

In 2018 the Lean process was initiated for DEM’s mineral production tenement renewals significantly reducing the number of steps required. (L–R): Cathi Buttfield holding the new draft process, Peter White showing the previous steps and Greg Marshall. (Photo 417593)

The Department for Energy and Mining (DEM) is always looking for ways to improve business processes in the ongoing effort to unlock the value of South Australia’s resources through the delivery of effective, efficient and transparent regulation. The 2019 year will see an increased focus on applying Lean business improvement principles across DEM with flow on benefits to industry and the community.

Lean is a systematic approach to reduce or eliminate activities that do not add value to business processes. The application of Lean principles across DEM provides multiple benefits by contributing to its strategic systems and streamlined process improvements, with improved customer focus, consistency, and outcomes for industry and other stakeholders. Internally there are increased productivity and staff satisfaction benefits as unnecessary steps are removed freeing up time to focus on customer delivery.

Recent Lean projects implemented by DEM include a review of the exploration licence application process, which has seen a substantial decrease in processing timeframes for a number of applications. In 2018, a Lean review of the mineral production tenement renewals process was initiated. This project is currently being finalised, and aims to ensure that 100% of adequate production tenement renewal applications be assessed one month before expiry.

The rollout of the Lean program across DEM has provided an excellent opportunity to raise feedback and suggestions that have been received over time from industry, the community, staff and other government agencies.

One of the key benefits of the way DEM is applying Lean, is that work areas have been able to start implementing improvements, making adjustments along the way that have helped immediately improve processes rather than wait until the project was completed. This knowledge is also being shared broadly with collaboration and learnings reaching across DEM.

Lean thinking is steadily becoming a fundamental part of the DEM’s culture, with many small improvements being implemented each week by individuals and teams.

– Cathi Buttfield, Peter White and Paul De Ionno, February 2019