Are bonds the answer?

An updated risk-based approach to manage environmental liabilities from petroleum and geothermal activities in South Australia has been developed and implemented. The significant body of research carried out by the Department for Energy and Mining for the policy considered the question of ‘Are bonds the answer to managing environmental liabilities?’.

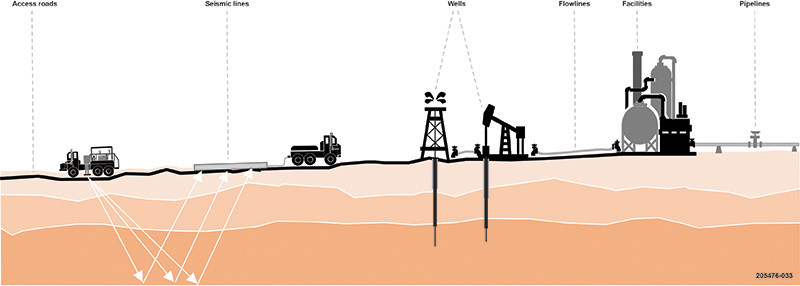

Environmental liabilities refer to the responsibility of operators to meet the costs of decommissioning and rehabilitation. For petroleum and geothermal activities, environmental liabilities include access roads, seismic lines, wells, flowlines, facilities and pipelines (Fig 1).

Figure 1 Environmental liabilities for petroleum and geothermal activities.

Traditionally operators pay a bond, cash deposit or full security for the environmental liability created when regulated activities commence. The bond is kept by the regulator until the operator has met its rehabilitation obligations. If an operator becomes bankrupt, the regulator can use the security to finance the cost of rehabilitation.

The updated policy considers the size of environmental liabilities and which petroleum and geothermal energy activities have the greatest liability and risk. It also recognises how liabilities are distributed and how operator risk may change. The policy draws on benchmarking results of how other regulators across the world manage environmental liabilities. It considers well productivity and reactivation and how that evidence can inform decisions on future use and rehabilitation. The policy also addresses the risks of expired well liabilities and transfer to high-risk operators.

The policy took effect from 1 July 2020 and has been welcomed by operators as a progressive, fair and balanced approach to managing environmental liabilities.

Operators are required to account for the status of all regulated activities each year, or on change of ownership. Wells that have not produced for more than 24 months require an assessment. If a future use can be demonstrated, the well is categorised as ‘inactive’. Inactive wells are subject to an annual fee which are deposited into a fund to finance the rehabilitation of wells that may become orphan. If no future use for a well is established, it is categorised as ‘expired’. Operators are responsible for decommissioning a minimum number of expired wells each year.

The department considers the risk of operators to meet their obligations in the assessment of financial security requirements using independent data sources. The proved reserves and credit health of operators are assessed to determine an appropriate level of financial security. The financial is adjusted commensurate with any change in risk each year or upon transfer of a licence to another operator. As a result, the amount of financial security is directly linked to operator risk and any change in environmental liabilities.

Since the policy took effect, smaller operators have submitted plans to reduce their financial security requirements by planning the rehabilitation of expired wells. The reduction of expired wells is also contributing to a reduction in the total environmental liability. Similarly, large oil and gas producers have submitted rehabilitation plans committing to rehabilitate 18 expired wells for the current year. Once rehabilitated, those wells will be removed from the rehabilitation liability estimate for producers in the subsequent annual assessments. The significant increase in rehabilitation is reducing the proportion of expired wells toward an acceptable level.

The updated environmental liability management policy research is published as a peer-reviewed paper and digital poster that was presented at the Australian Petroleum Production & Exploration Association (APPEA) Conference in Perth in June 2021. The poster presents the research work and features a case study of how the policy applies to an operator and initial implementation results.

Updated policy and materials developed for APPEA 2021

– Scott Cawrse, June 2021