High-purity alumina and silicon are new additions to Australia’s critical minerals list.

The national 2022 Critical Minerals Strategy released in March builds on the first strategy published in 2019. Of significance to South Australia is the inclusion of the 2 new minerals, which both occur in our state: high-purity alumina and silicon (Fig 1).

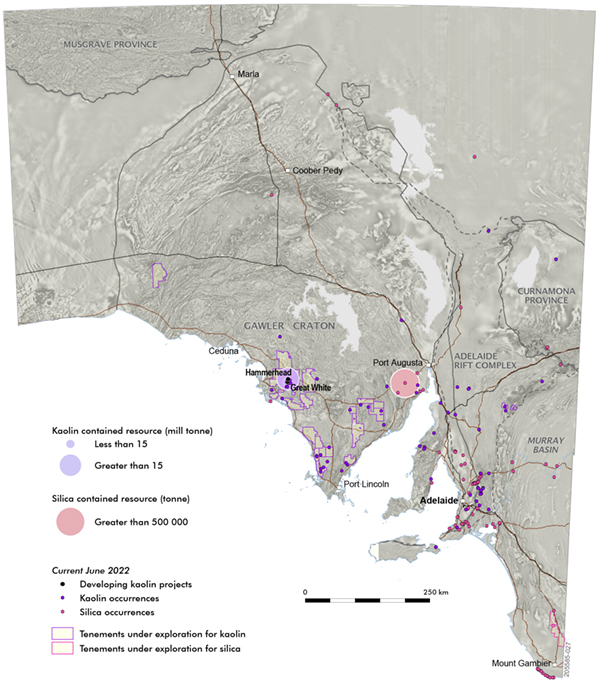

Figure 1 Kaolin and silica resources in South Australia.

Along with the update to the critical minerals list, key aspects of the strategy are:

- renewing focus on downstream refining, manufacturing and battery integration and services capabilities

- supporting the Critical Minerals Accelerator Initiative

- establishing a virtual Critical Minerals Research and Development Centre

- establishing strategic international critical minerals partnerships

- working with states and territories to establish regional hubs.

The strategy addresses the fast technological development in resourcing critical minerals for the defence, aerospace, automotive, renewable energy, telecommunications and agritech industries.

Thinking Critical South Australia complements the strategy and aims to boost downstream critical minerals opportunities in South Australia. Innovators, entrepreneurs and businesses across the globe were invited to become a part of the state’s leading critical minerals sector (see December 2021 news article). Five winners were announced on 8 July 2022 and will share a prize pool of $250,000+ to help establish their businesses in South Australia.

These winning projects include the development of a unique nano technology battery which converts radioactive decay energy for use in long lasting batteries, advances in comminution technologies to reduce greenhouse gas emission as well as water and energy use, space technology and innovative industrial instrumentation.

Watch the live winners announcement

The Geological Survey of South Australia has also received funding for a new critical minerals project which will improve the understanding of the states’ critical mineral potential. This project, along with the others already discussed will ensure South Australia is at the forefront of the critical minerals sector.

High-purity alumina

High-purity alumina (HPA) is a form of aluminium oxide (Al2O3) with very low levels of impurities. It is a step along the value chain from aluminium, and it can be produced from kaolin clay or processed bauxite. It is chemically inert, does not conduct electricity and has a very high melting point.

HPA is used in the automotive and aerospace sector and is an important component in lithium-ion batteries, electronics, LED lights and scratch-resistant glass used in watches and smartphones.

Aluminium is listed as a critical mineral by the United States, Canada and the European Union. China and India are some of the world’s largest consumers of HPA due to a growing demand in LED bulbs and a rapidly growing medical sector. The global HPA market was valued at $1.3 billion in 2019 and is projected to grow to $4.8 billion by 2026 (High purity alumina market, Allied Market Research website). Australia has potential to produce HPA to meet growing global demand thanks to our strong primary aluminium industry and high-purity kaolin clay deposits.

Traditional production of HPA from aluminium requires a lot of energy. However, alternative processing techniques can now produce HPA from kaolin clay. High-purity kaolin is abundant in South Australia, with projects including: Andromeda’s Great White Kaolin Project (mining lease granted; program for environment protection and rehabilitation, PEPR, pending); iTech Minerals’ kaolin projects on the Eyre Peninsula and in the Nackara Arc region; and Power Minerals’ Eyre Peninsula Kaolin Project.

Read more about kaolin in South Australia

Silicon

Silicon in its pure form is a hard, brittle crystalline solid; it is a metalloid and a semiconductor. Silicon is the second most abundant element in the Earth’s crust, found in various forms of silica and silicate minerals. High-quality silica sand is a raw ingredient for applications requiring silicon metal.

Silicon is used in high tech applications including electronics, LCD panels, semiconductors and photovoltaics.

Silicon metal is listed as a critical mineral by the European Union, Japan and India. Although silica sand is plentiful on Earth, high-grade silica sand is rare and in demand due to the requirement for very low impurities and sourced sand which meets environmental and socially responsible benchmarks. Construction sands are used for their physical properties alone, while high-grade silica sands are valued for a combination of chemical and physical properties (Australian silica sand sector report, Terra Studio website).

While South Australia produces silica from sands for glass making, the potential for producing metallurgical-grade gravels (99.5% silica) for silicon metal production is yet to be investigated.

Read more about silica in South Australia

– Corri Baker and Carmen Krapf, July 2022