Adrian Fabris

Geological Survey of South Australia, Department of the Premier and Cabinet

Download this article as a PDF (2.8 MB); cite as MESA Journal 85, pages 24–30

Introduction

There has been a dramatic decline in the discovery of major new mineral deposits in Australia since around the early 2000s (Guj and Schodde 2013). The decline is generally attributed to most outcropping mineral deposits having been found, driving the need to develop new techniques and methods to improve discovery rates through cover sediments and rocks. This is of particular relevance to South Australia where much of the state’s prospective geology is covered by younger sediments which significantly impede exploration and discovery. The good news for South Australia is that if exploration success rates through cover can be improved, the full potential of our likely mineral wealth can be achieved.

The Mineral Systems Drilling Program (MSDP), which took place between July 2015 and April 2016 along the southern Gawler Ranges, was a collaborative drilling project between the Geological Survey of South Australia (GSSA), Deep Exploration Technologies Cooperative Research Centre (DET CRC), mineral explorers, service providers and research institutes, namely:

- mineral explorers Minotaur Exploration and Kingston Resources

- services companies Boart Longyear, Imdex, Globaltech, Olympus, Epslog and Bureau Veritas

- researchers from CSIRO, the University of Adelaide and Curtin University.

The primary aim of the MSDP was to develop new geological knowledge across the southern Gawler Ranges; however, progressing the development of new technologies that will contribute to improving exploration beneath cover was an important aspect, and involved trials of technologies being developed within DET CRC (DET CRC 2017b; Hillis et al. 2014). The ‘pull through’ and learnings from the MSDP trials are relevant to the entire minerals industry. The emphasis on high-calibre geoscience collaborations across geoscience sectors, and commitment to the application and testing of new exploration technology within the program, sets the MSDP apart from other government-run drilling programs. The MSDP was world-first in adopting this type of collaborative arrangement between government, researchers, mining industry and service companies. The MSDP provided the platform for engaging and drawing together diverse and innovative research in the minerals sector. It also provided the opportunity to showcase and test precommercial products in a semi-commercial environment. A through-chain collaboration of this type is virtually unknown in the world of geoscience and mineral exploration.

This article is intended as complementary to a summary of geological outcomes from the MSDP, also presented in this edition of the MESA Journal. This article focuses on outcomes of technology trials and the collaborative benefits of the MSDP. The reader is referred to Fabris et al. (2017) for a more comprehensive review of the background and aims for each technology deployment.

Technology trials

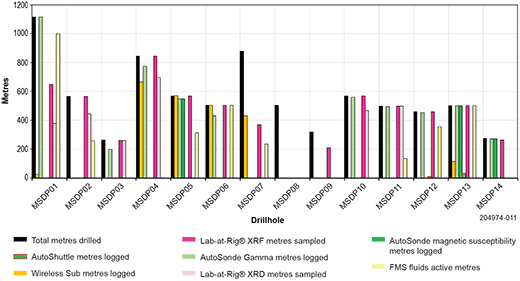

DET CRC was established with the objective of developing transformational technologies for successful mineral exploration through thick cover rocks to be utilised and commercialised by the mineral exploration industry. DET CRC technologies were deployed in most of the 14 MSDP drillholes over a nine-month period, representing a significant opportunity for research, development and testing during the program (Fig. 1). These technologies aim to deliver real-time information and data analysis during a drill program (Hillis et al. 2014). The technologies featured in the MSDP included downhole and top-of-hole sensors.

Wireless Sub

The Wireless Sub is attached to the top of the drill string and accurately measures drilling parameters such as the downward force on the drillbit, rate of penetration, fluid pressure and rotation speed, enabling the driller to optimise drilling performance and maximise productivity (Fig. 2). The objective of the MSDP trial was to demonstrate the reliability and robustness of the technology and facilitate the rapid development of the Wireless Sub towards commercialisation. The extended period of testing in a harsh drilling environment allowed the technology to be thoroughly evaluated, and provided an opportunity to validate its reliability and precision. During trials, the Wireless Sub progressed from a 1st generation prototype through to a more robust and reliable 2nd generation unit which underwent significant testing. A real-time rig display was designed and deployed during the MSDP. The Wireless Sub was licenced for commercialisation shortly after the conclusion of the MSDP (DET CRC 2016b), with testing on the program critical in convincing the licensee, Boart Longyear, that the technology was both useful and reliable.

Figure 2 The Wireless Sub sits on the top drive of the drill rig and measures drilling parameters.

Figure 2a Wireless Sub. (Courtesy of DET CRC; photo 416136)

AutoSonde and AutoShuttle

Figure 3 Boart Longyear drillers preparing the multi-sensor AutoSonde for deployment on MSDP13. (Courtesy of DET CRC; photo 416134)

The AutoSonde and AutoShuttle collect geophysical wireline log type data (gamma, magnetic susceptibility and resistivity) without separate mobilisation of a wireline logging crew or additional time requirements at the drillsite (Fig. 3). The AutoSonde is deployed into the hole by the driller and analyses the drilled profile as the drill rods are pulled out of the hole. The AutoShuttle sits behind the core barrel and acquires measurements while drilling, returning data every time the core barrel is retrieved. Both technologies are a rapid and cost effective means of collecting geophysical data that circumvent the issue of full or partial collapse of a hole which prevents the subsequent deployment of logging equipment.

The MSDP trial demonstrated the reliability and robustness of the AutoSonde’s prototype total count gamma sensor, and the subsequent prototype which included a magnetic susceptibility sensor. As a precommercial product, it was important to demonstrate that field drilling personnel could reliably deploy the AutoSonde. Trials resulted in the development of robust data collection and processing workflows and demonstrated that field drilling personnel could reliably deploy, collect and transmit raw data for processing.

While a commercialisation agreement was reached with Boart Longyear for the AutoSonde with total count gamma sensor before the start of the MSDP (January 2015), the MSDP provided an ideal precommercial test environment with learnings fed back into future product design which has assisted with bridging the so called ‘commercialisation valley of death’ (being the gap between research and commercial worlds). The AutoSonde, rebadged the TruProbe™ by Boart Longyear, was recently deployed during the GSSA Coompana drill program (April–September 2017).

The MSDP was the first full field trial of the AutoShuttle outside of the Brukunga Drilling Research & Training Facility in the Adelaide Hills. A comparison of total count gamma results showed the fidelity possible by using the AutoShuttle due to the increased reading time. Following the MSDP trials, DET CRC has accepted a commercialisation proposal from Boart Longyear for the magnetic susceptibility and resistivity sensors on the AutoSonde and for the AutoShuttle.

Lab-at-Rig®

Figure 4 Lab-at-Rig® deployed during MSDP. (Courtesy of DET CRC; photo 416133)

Lab-at-Rig® enables state-of-the-art on-site analysis of drill cuttings, and provides near real-time XRF geochemistry and XRD mineralogy (Fig. 4). These data can be used to aid geological logging and allow greater confidence in assessing the prospectivity of drill core. The focus of testing during the MSDP was on improvement and development of design configurations, sample capture and sample preparation techniques. This also involved better integration with a solids removal unit. Delivery of data to clients was also tested, and involved data streaming via a dedicated satellite system and delivery through to ReflexHub, which was launched during the program. Workflows for real-time data analysis were trialled. Lab-at-Rig® operated for the majority of the drill program and had no issue with 24-hour operation.

Geochemical data from drill cuttings were available within a few hours of being drilled and provided an extraordinary ability to remotely assess lithology and mineral prospectivity while drilling was in progress. In the field, having geochemical analyses at ~1 m resolution for an entire hole was a rare luxury and was used to aid core logging (including subtle intraformational variation as well as major breaks) and highlight mineralised intersections. It also enabled correlation with mineralogy to provide a more thorough understanding of influences on elemental variation (protolith vs alteration). Contamination from excessive bit wear (Cu, W ± Ag) and rod grease (Zn) was evident in results, however, could be corrected using known ratios from drillbit compositions.

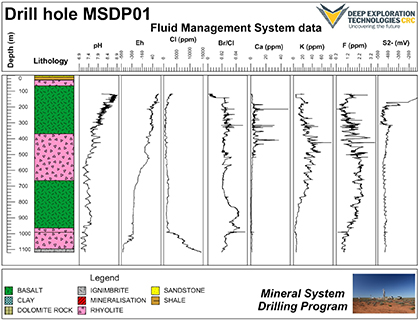

Fluid Management System

The Fluid Management System (FMS) utilises a series of ion selective electrodes to provide real-time information on the chemistry of the drilling fluids (Fig. 5). Sulfide intervals and changes in aquifer chemistry can be detected. Significant learnings and development made during the MSDP resulted in design changes and a practical workflow for use in field conditions. Dramatic changes in drill fluid chemistry resulting from additives highlighted the possible commercial application of using the system to maintain optimal fluid condition for efficient drilling.

Figure 5 The Fluid Management System utilises a series of ion selective electrodes to monitor drill fluid chemistry.

Real Time Drill Site

The objective of the Real Time Drill Site (RTDS) was to develop and deliver ICT architecture to integrate geoscience data generated by DET CRC’s analytical technologies during the MSDP, and allow those data to be interrogated, analysed and visualised. This was in support of the vision of real-time data analysis and exploration in the mineral industry that is currently in its infancy. Software development was facilitated by funding gained from the South Australian Mining Industry Participation Office and utilised South Australian based developers. A demonstration of the RTDS ‘dashboard’ was held towards the end of the MSDP and enabled Wireless Sub and AutoSonde data to be integrated and viewed through a secure portal (utilising Reflex Hub), anywhere in the world (Fig. 6).

Seismic acquisition for the minerals industry

Several targeted, cost-effective surface seismic surveys and downhole vertical seismic profiles (VSP) were conducted by Curtin University and DET CRC to aid depth to basement estimation around MSDP drillholes and refine the methodology for using seismic in hard rock terrains. To contain costs, inexpensive sources and sparse geophone spacing with small crews were used. Different geometries, acquisition systems and imaging methodologies were trialled. Most novel were the evaluation of a draggable receiver string seismic system and the use of optic fibre as receivers during VSP surveys. It was concluded that the draggable receiver string could be effective at imaging to 100 m depth. In-hole optic fibre distributed acoustic sensors delivered faster and higher quality data than hydrophone VSP (DET CRC 2017a). This indicates the potential to gain velocity characterisation in drillholes at very low cost, opening up the possibility that it will become part of routine petrophysical data acquired during a drill program.

RoXplorer® trial

Figure 7 RoXplorer® on deployment at Port Augusta field site as part of the broader MSDP project. (Courtesy of DET CRC; photo 416155)

Following completion of the 14 MSDP diamond drillholes, DET CRC’s new coiled tubing drilling rig, the RoXplorer®, was deployed on the same drill pad as MSDP02 (Fig. 7; Fabris 2017; DET CRC 2017b). The site provided an example of thick cover of sedimentary rocks typical of the Stuart Shelf and a target zone of ~1% Cu at the contact between Tapley Hill Formation and Beda Basalt at 398 m. In addition to these geological attributes, inclusion of the RoXplorer® trial as a component of the broader MSDP provided permitting and logistics advantages, which enabled researchers to focus on achieving a successful drillhole, in what was the first full field trial of RoXplorer®. At completion of this trial, DET CRC had realised the milestone of drilling a 20 m interval in under one hour and demonstrated that the RoXplorer® could retrieve cuttings that sharply define geological boundaries. Furthermore, assays of cuttings collected during drilling closely matched those obtained from the diamond core in MSDP02. The trial was a significant demonstration that DET CRC’s flagship technology, a coiled tubing drill rig designed for mineral exploration, was a viable method of addressing their objective of cheaper, faster drilling. It also meant all key technology developments within DET CRC were tested during the MSDP.

Trials during the MSDP have played a tangible role in moving these technologies closer to commercial products. All technologies were demonstrated or successfully adapted to meet the challenges provided by remote and sometimes harsh climatic conditions. One measure of success is through progress along Schild’s (2014) technology readiness levels (TRL). All technologies progressed at least one level against TRLs (Table 1).

Explanations, demonstrations and benefits of technology trials have been presented in a video series available through the DET CRC TV channel.

Table 1 Improvements to technology readiness levels through technology deployment, testing and development during the MSDP.

| DET CRC technology in MSDP | TRL stage move in MSDP | |

|---|---|---|

| August 2015 | May 2016 | |

| Wireless Sub | 5 | 6 |

| AutoSonde – total gamma | 5 | 6 |

| AutoSonde – magnetic susceptibility | 3 | 4 |

| AutoShuttle | 4 | 6 |

| Lab-at-Rig® XRF and XRD | 6 | 7 |

| Fluid Management System | 4 | 6 |

| Real Time Drill Site | 2 | 5 |

| Seismic exploration for hard rock environments | 3 | 5 |

Technology readiness level stages (Schild 2014)

TRL 0 Idea. Unproven concept, no testing has been performed.

TRL 1 Basic research. Principles postulated and observed but no experimental proof available.

TRL 2 Technology formulation. Concept and application have been formulated.

TRL 3 Applied research. First laboratory tests completed; proof of concept.

TRL 4 Small-scale prototype. Built in a laboratory environment (‘ugly’ prototype).

TRL 5 Large-scale prototype. Tested in intended environment.

TRL 6 Prototype system. Tested in intended environment close to expected performance.

TRL 7 Demonstration system. Operating in operational environment at precommercial scale.

TRL 8 First of a kind commercial system. Manufacturing issues solved.

TRL 9 Full commercial application. Technology available for consumers.

The benefits of collaboration

A core principle of the MSDP was to foster collaboration. Thirteen organisations collaborated: 8 industry, 4 research and the South Australian Government. The program accessed a range of expertise from across government to ensure activities followed best practice. These included the areas of Aboriginal heritage, community engagement, safe work practices, land access and rehabilitation. Within the GSSA, regional mapping and data collection projects were modified and integrated with the drill program to maximise the benefits from coordinated activities across a range of disciplines. The South Australian Government’s investment of $2.5 million from the PACE Frontiers and PACE Copper initiatives was leveraged into an overall ~$8 million cash and in-kind program. This leverage was achieved due to integrated research required to achieve the program, which grew as project parties fully realised the potential benefits. The collaborations increased the leverage of financial and in-kind contributions, significantly improving outcomes.

Industry participants, Minotaur Exploration and Kingston Resources, achieved additional metres of drilling and access to near real-time data in which to make assessments of the geology and prospectivity. DET CRC and associated researchers and service providers gained access to a semi-commercial environment in which to deploy, test, improve and redeploy technology over a nine-month period. Not only did the GSSA leverage ~$1 million in cash and at least $2 million in-kind from collaborators, but also gained access to industry knowledge and expertise, and additional sample analyses to add to the evaluation of an emerging new mineral district.

In excess of 100 South Australian based suppliers were used during the program (DET CRC 2016a) from trucking water and grading roads to preparation of 3,225 meals. This represents a flow on of the broader benefits of the program to regional South Australia.

Conclusion

The MSDP provided an opportunity to showcase and test precommercial technology within a supportive real-life exploration program. All technologies were successfully deployed during the MSDP with significant progress made, not only to hardware and software, but also deployment procedures and protocols. An improved understanding of skills and training requirements was identified for routine use of these technologies in future drilling programs. The technologies deployed during the MSDP provide the wider exploration community the opportunity to gain an early insight of how data from new technologies will better inform future exploration geoscientists, accelerate decision-making and eventually lower the cost of exploration.

The success and impact of technology trials during the MSDP is due largely to the successful model deployed by DET CRC, which supports the progress of research and development through to commercial products that are aligned with the objectives of DET CRC. While the technologies alone will not transform the exploration success rate beneath barren cover, they provide a step change in the approach to acquiring data in a cost-effective and timely manner. This will permit more test holes to be drilled based on evaluation of real-time data; both are widely acknowledged as essential to improving success of mineral exploration through cover.

The program served as a model for collaboration in the way that it brought together mineral explorers, DET CRC, the mining equipment, technology and services (METS) sector, government and research organisations. The outcomes include improved understanding of the state’s geology and an impetus to grow the state’s METS sector through leveraged activity from the licence of new intellectual property.

Acknowledgements

The MSDP was part of South Australia’s PACE Frontiers and PACE Copper initiatives which form part of South Australia’s Copper Strategy. Valuable contributions (technical, staffing and financial) were received from collaborative partners Minotaur Exploration, Kingston Resources and DET CRC.

Technology deployment was supported by DET CRC whose activities are funded by the Australian Government's Cooperative Research Centre Program.

Curtin University managed seismic acquisition and processing.

The measure of improvement of DET CRC technology using the TRL scale was prepared by Robbie Rowe (GSSA).

References

Deep Exploration Technologies Cooperative Research Centre 2017b. The future of drilling. AusIMM Bulletin June 2017:56–59.

DET CRC – see Deep Exploration Technologies Cooperative Research Centre

Guj P and Schodde R 2013. Where are Australia’s mines of tomorrow? AusIMM Bulletin June 2013:76–82.

Hillis RR, Giles D, van der Wielen SE, Baensch A, Cleverley JS, Fabris AJ, Halley SW, Harris BD, Hill SM, Kanck PA, Kepic A, Soe SP, Stewart G and Uvarova Y 2014. Coiled tubing drilling and real-time sensing—enabling prospecting drilling in the 21st century? In KD Kelley and HC Golden eds, Building exploration capability for the 21st century, Special Publication 18. Society of Economic Geologists, Littleton, CO, pp. 243–260.

Schild P 2014. Summary of the calls open in 2014, [Calls – overview], presentation. Horizon 2020 Energy Information Day - 2014 and 2015 calls, 5 December 2013, Charlemagne, Brussels. Horizon 2020.