TECHNICAL REGULATOR SOUTH AUSTRALIA

Level 8, ANZ Building

11 Waymouth Street, Adelaide SA, 5000

GPO Box 320, Adelaide SA, 5001

www.sa.gov.au/otr

Contact phone number: Robert Faunt (08) 8226 5500

Contact Facsimile: (08) 8226 5529

Contact email: DEMOTRMail@sa.gov.au

ISSN: 1832-8687

Date presented to Minister: 29 September 2023

Annual Report of the Technical Regulator 2022-2023

This document describes the operations of the Technical Regulator in the electrical, gas, plumbing and water industries.

The Technical Regulator is a statutory office established by:

- Section 7 of the Electricity Act 1996;

- Section 7 of the Gas Act 1997; and

- Section 8 of the Water Industry Act 2012.

Robert Faunt has held this office since he was appointed as the Technical Regulator under the Electricity Act 1996 and the Gas Act 1997 on 28 February 2003, and since he was appointed as the Technical Regulator under the Water Industry Act 2012 in 2012.

Note: All photographs in this report have been used with the permission of the relevant provider.

To:

Honourable Tom Koutsantonis MP

Minister for Energy and Mining

This annual report will be presented to Parliament to meet the statutory reporting requirements of Electricity Act 1996 (Sec 14), Public Sector Act 2009 and the requirements of Premier and Cabinet Circular PC013 Annual Reporting.

This report is verified to be accurate for the purposes of annual reporting to the Parliament of South Australia.

Submitted on behalf of the OFFICE OF THE TECHNICAL REGULATOR by:

Rob Faunt

Technical Regulator

Date 29 September 2023

Contents

Annual Report of the Technical Regulator 2022-2023

THE OFFICE OF THE TECHNICAL REGULATOR

General Activities of the Office of the Technical Regulator

Section 2: Technical and Safety Regulation

Section 3: Participation in Standards

Section 4: Emergency Management

Section 5: Consumer Safety Awareness

Section 6: Energy and Water Ombudsman SA

Volume I – Electricity Industry Preface

Section 7: Electrical Infrastructure

Section 8: Electrical Installation

Section 9: Electrical Products

Section 10: Electricity Regulatory Coordination

Volume II – Gas Industry Preface

Section 11: Gas Infrastructure

Section 14: Gas Regulatory Coordination

Volume III – Water Industry Preface

Section 15: Water and Sewerage Infrastructure

Section 16: Plumbing Installation

Section 17: Consumer Safety Awareness

Section 18: Water and Plumbing Regulatory Coordination

APPENDIX 1: OTR ACTIVITY REPORT – 2022-2023

Overall Activities for 2022-2023

Volume I – Electrical Industry

Section A2: Electrical Infrastructure

Section A3: Electrical Installations

Section A4: Electrical Products

Section A5: Electrical Safety Awareness

Section A6: Gas Infrastructure

Section A9: Gas Regulatory Coordination

Volume III – Water and Plumbing Industry

Section A10: Water and Sewerage Infrastructure

Section A11: Plumbing Installations

Section A12: Plumbing Products

Section A13: Regulatory Coordination

Volume IV – Key Performance Indicators

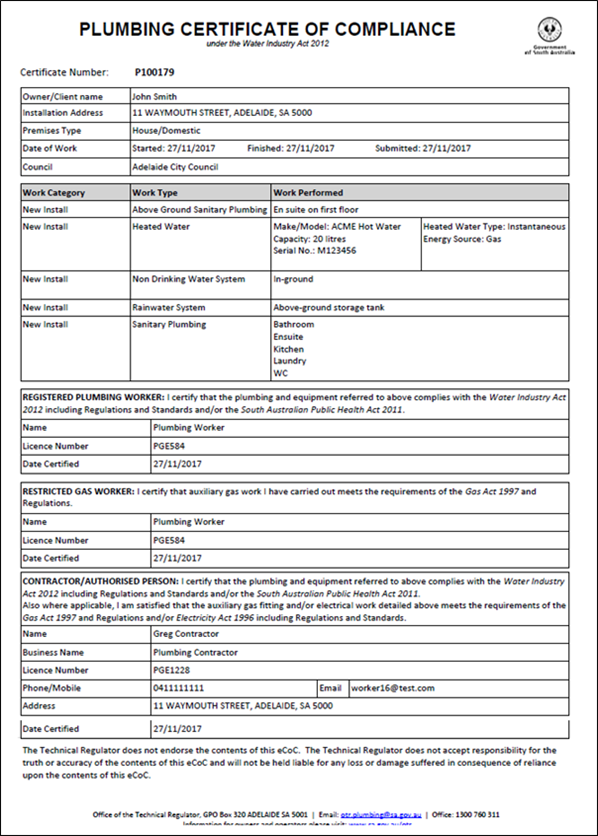

Appendix 3: Electronic Certificates of Compliance Form

Appendix 4: Electrical Products

A4.1. Proclaimed Electrical Products

Appendix 5 Electrical definitions, formulas and units

A5.2. Performance Indicator Definitions

A5.3. Performance Indicator Formulae

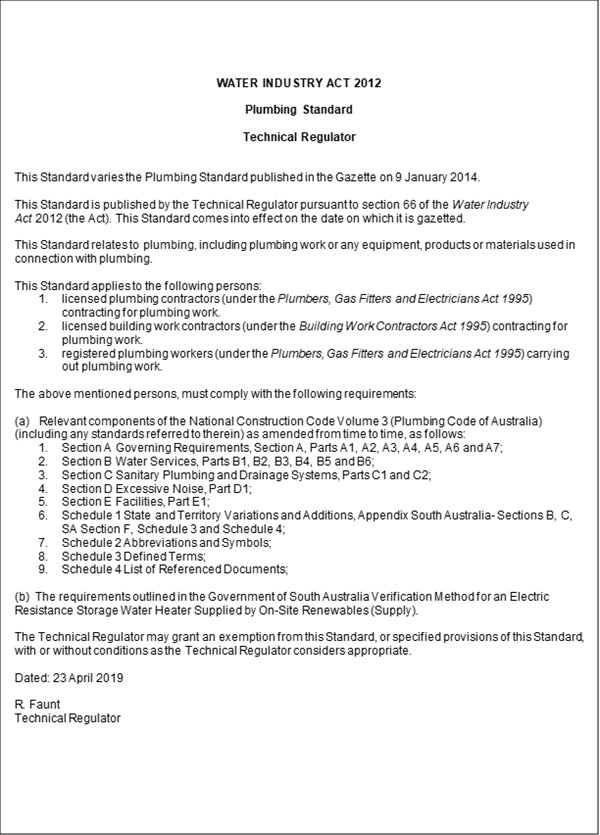

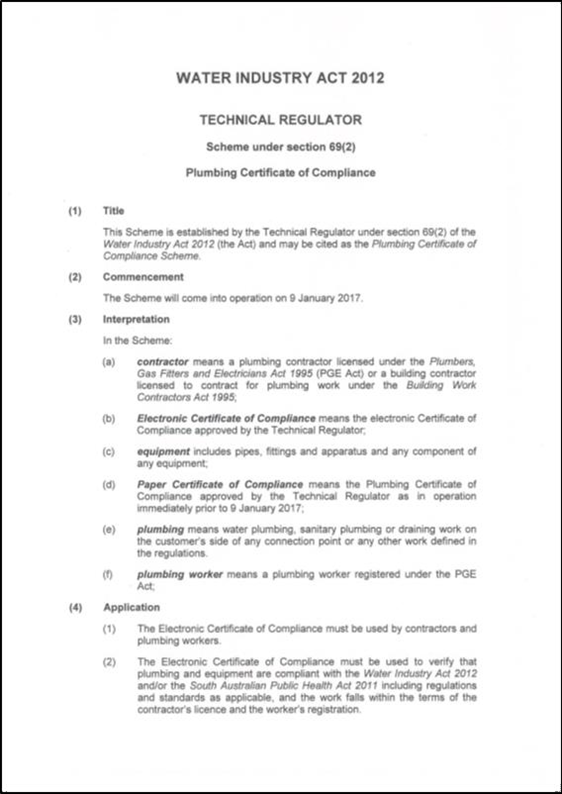

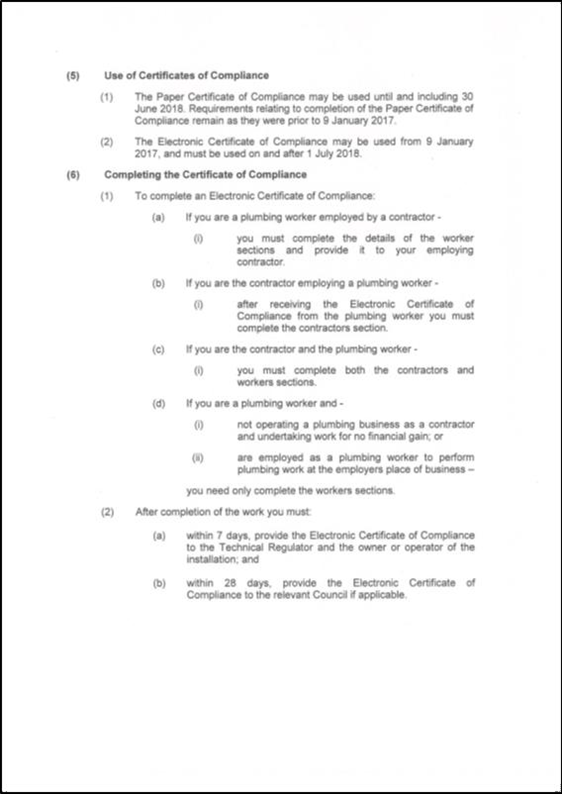

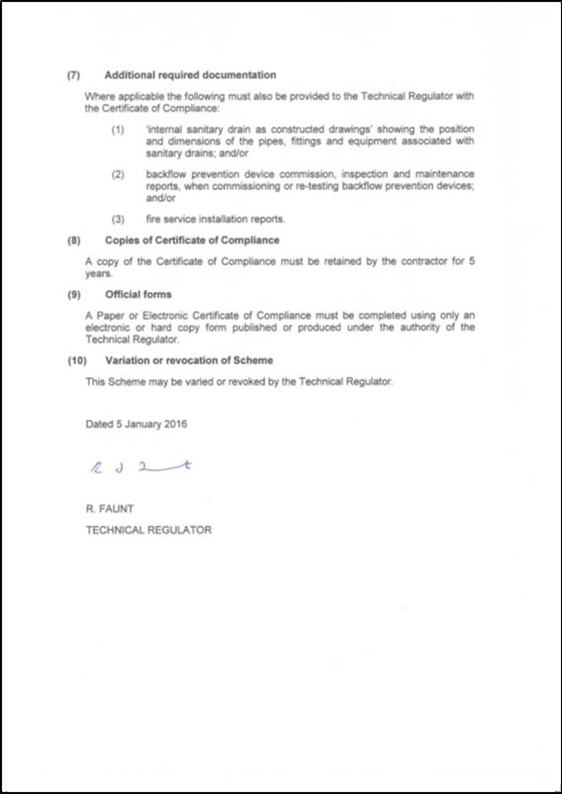

Appendix 7: Scheme for Plumbing Certificates of Compliance

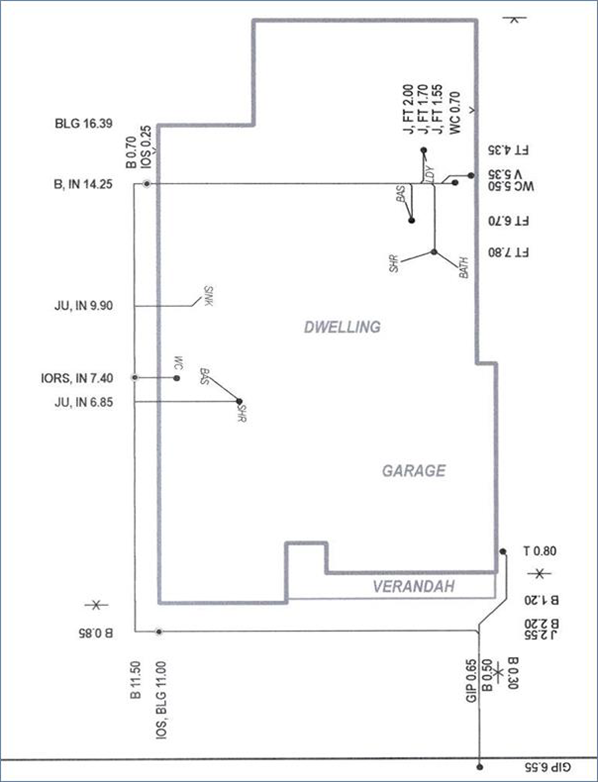

Appendix 8: Example of internal Drain as Constructed Drawing

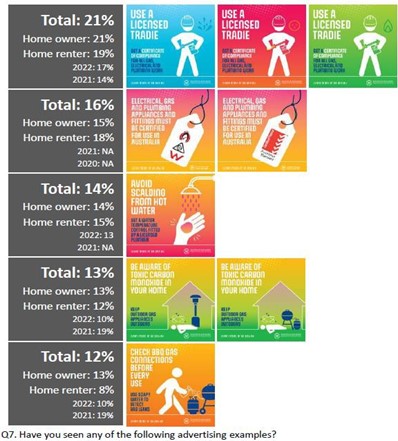

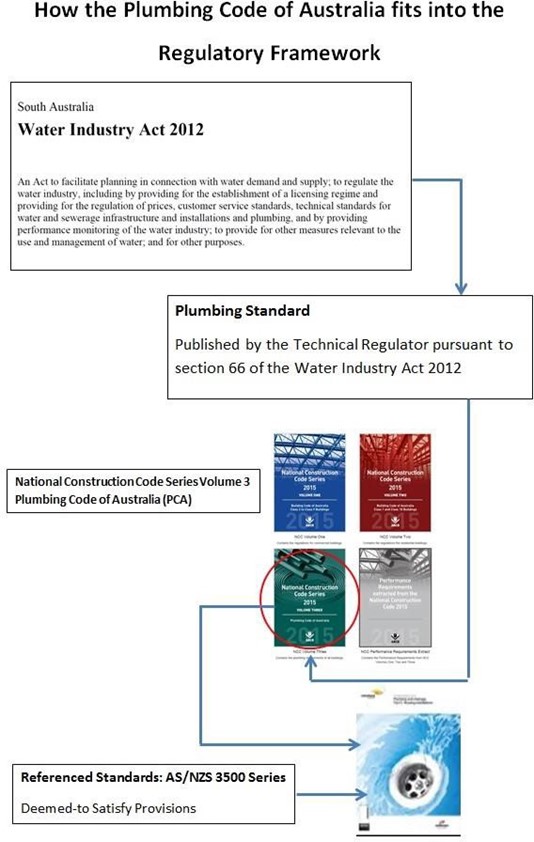

Appendix 9: Plumbing Code within the regulatory framework

Appendix 10: Water Industry Entities and licences

Appendix 11: Glossary and Abbreviations

List of Figures

Figure 1: Example of Regulation Roundup

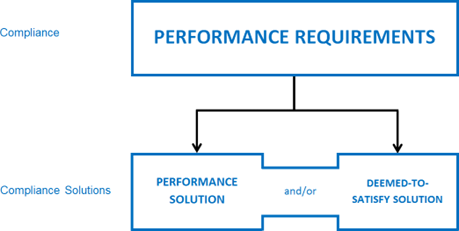

Figure 2: Example of safety awareness campaign advertisements

Figure E 1: Non-compliant electrical installation at a major event

Figure E 2: Boundary of installations from products

Figure E 3: Regulatory Compliance Mark

Figure E 4: Example of approval labelling for an OTR (S marking) approved product – wall switch

Figure E 5: Example of the RCM approval labelling symbol for an approved product – desk lamp

Figure E 6: Example of approval labelling for regulatory authority NSW Fair Trading – laptop charger

Figure E 7: Example of an electrical product failure

Figure E 8: Example of an electrical product failure

Figure E 9: Incident due to user not observing the warning instructions

Figure G 1: Southern and eastern Australian gas fields and major pipelines

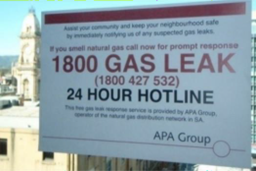

Figure G 2: The APA Group emergency/gas leak reporting number (1800 GAS LEAK – 1800 427 532)

Figure G 3: HDPE mains replacement

Figure G 4: Gas storage tank compound

Figure G 5: New Air Dryer (Type B appliance) undergoing commissioning and Type B testing

Figure G 6: Preowned resin sand dryer (Type B appliance) undergoing modifications and installation

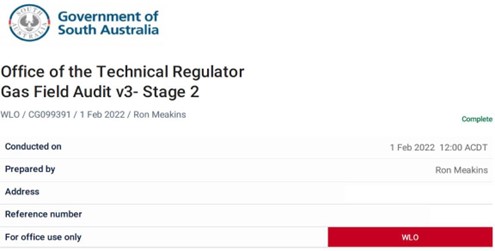

Figure G 7: Example of gas e-audit form

Figure G 8: Example of a damaged gas hose on a temporary cooking setup at an outside event

Figure G 9: Example of non-compliant portable generators

Figure G 10: Example of a communal cooking facility at a caravan park that required modification

Figure G 11: Examples of LPG effect fires used at outdoor events

Figure G 12: Gas BBQ fire due to gas leaking from the high-pressure POL connection

Figure G 13: House fire because of an incorrect DIY appliance installation

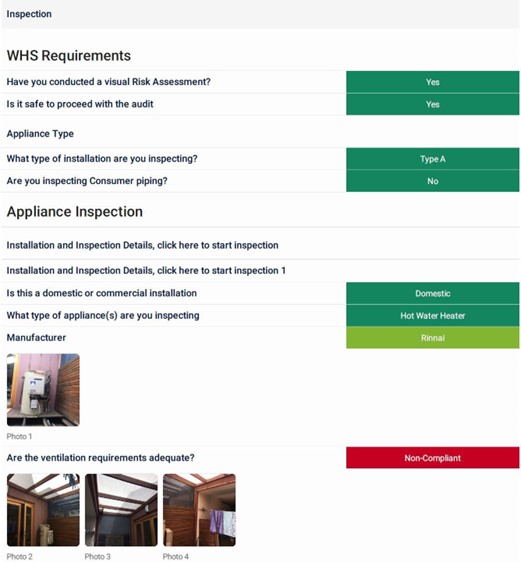

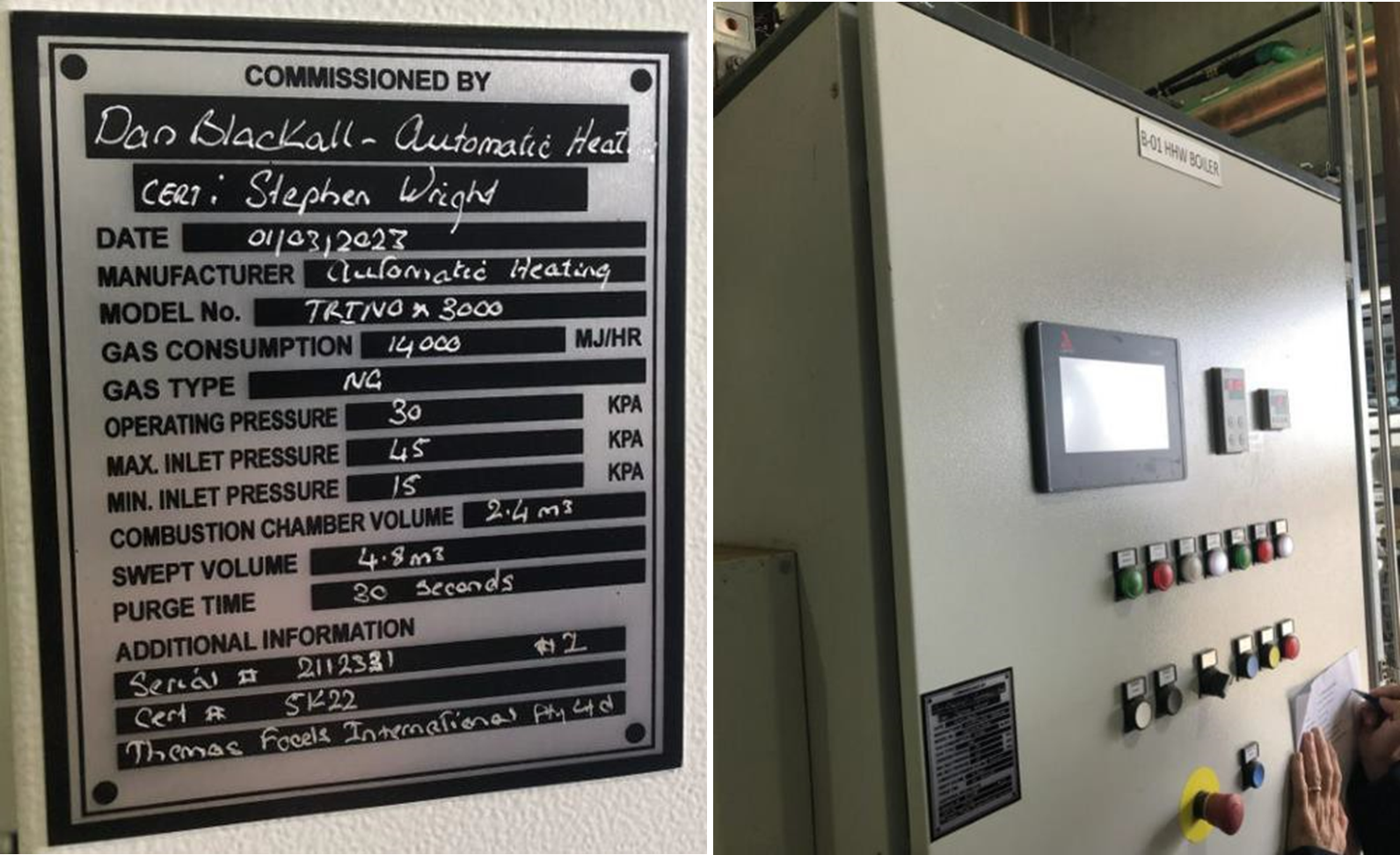

Figure G 14: Certification Label Examples

Figure G 15: Information Data Plate including certification number, warning, and certification label

Figure G 16: Information Data Plate including certification number and certification label

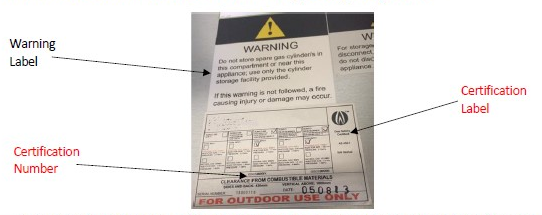

Figure W 1: Split between services provided by water industry entities in South Australia

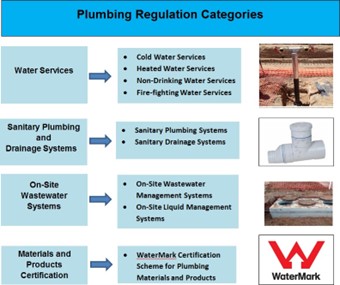

Figure W 2: Plumbing categories that are monitored and regulated through on-site audits by the OTR

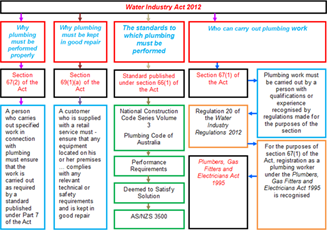

Figure W 3: Details of plumbing obligations under the Water Industry Act 2012

Figure W 4: Examples of Plumbing and Drainage Installations in residential developments

Figure W 5: Commercial Drainage Installation

Figure W 6: New Royal Adelaide Hospital under construction

Figure W 7: Technical Regulator audit of inground fire system

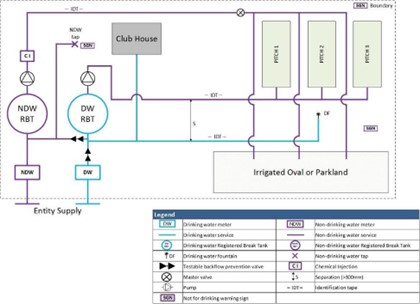

Figure W 8: Areas of metropolitan Adelaide with non-drinking water

Figure W 9: example of non-drinking water signage

Figure W 11: Drinking and non-drinking water meters

Figure W 12: Plumbing installation showing in-wall non-drinking and drinking water pipework

Figure W 13: Fire Service Installation with Backflow Prevention Device

Figure W 14: Variation to a standard fire hydrant booster service

Figure W 15: Reduced Pressure Zone Backflow Devices in in-wall stainless steel tundish box

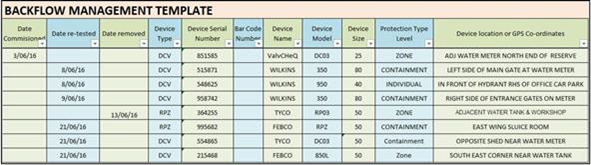

Figure W 16: Example of a section of a backflow management template

Figure W 17: Examples of Plumbing Advisory Notes

Figure W 18: Training session conducted by the OTR plumbing section at Tonsley TAFE

Figure W 19: NCC Compliance Structure

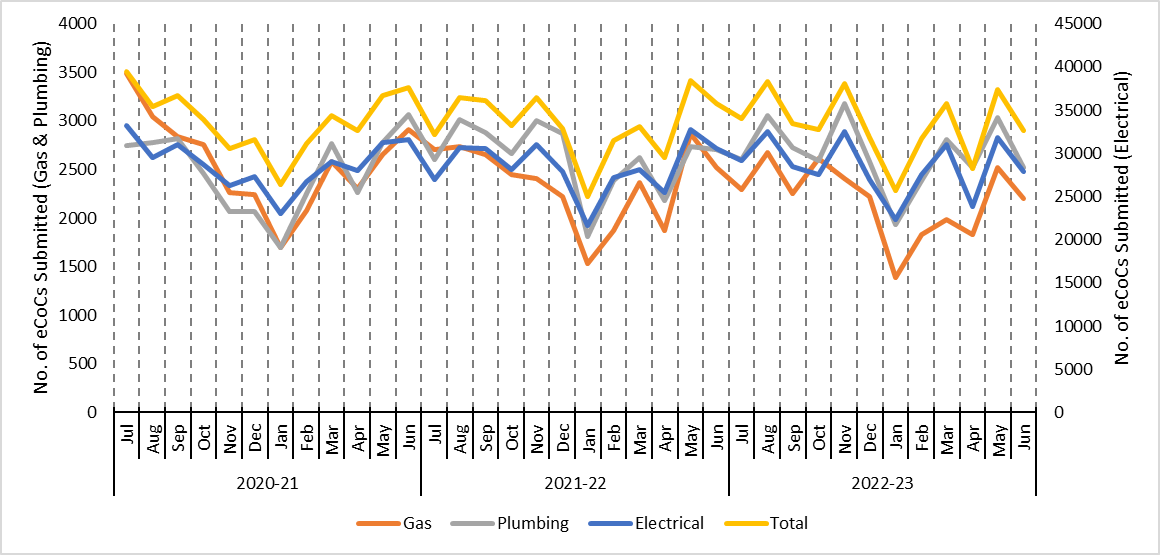

Figure A1- 1: Electronic Certificate of Compliance Submission Rates by Industry

Figure A1- 2: Survey participants recalled seeing or hearing Consumer campaign for 2023

Figure A1 E 1: Visy Board Solar and BESS equipment

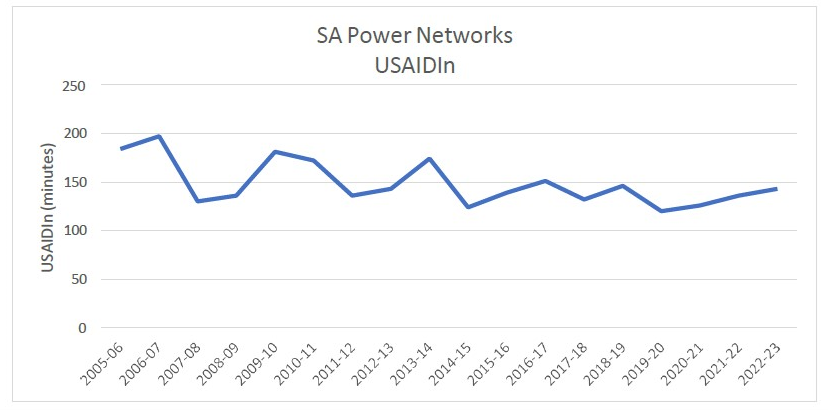

Figure A1 E 2: State-wide Unplanned SAIDI for SA (minutes per customer)

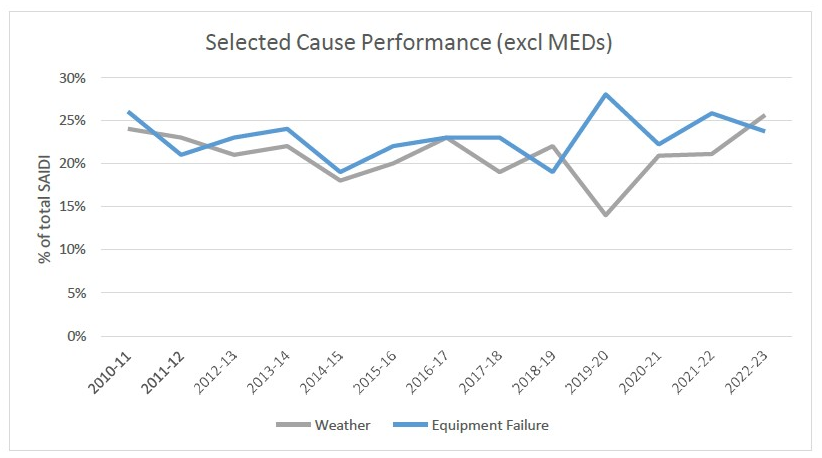

Figure A1 E 3: Contribution to State-wide SAIDI for SA (minutes per customer)

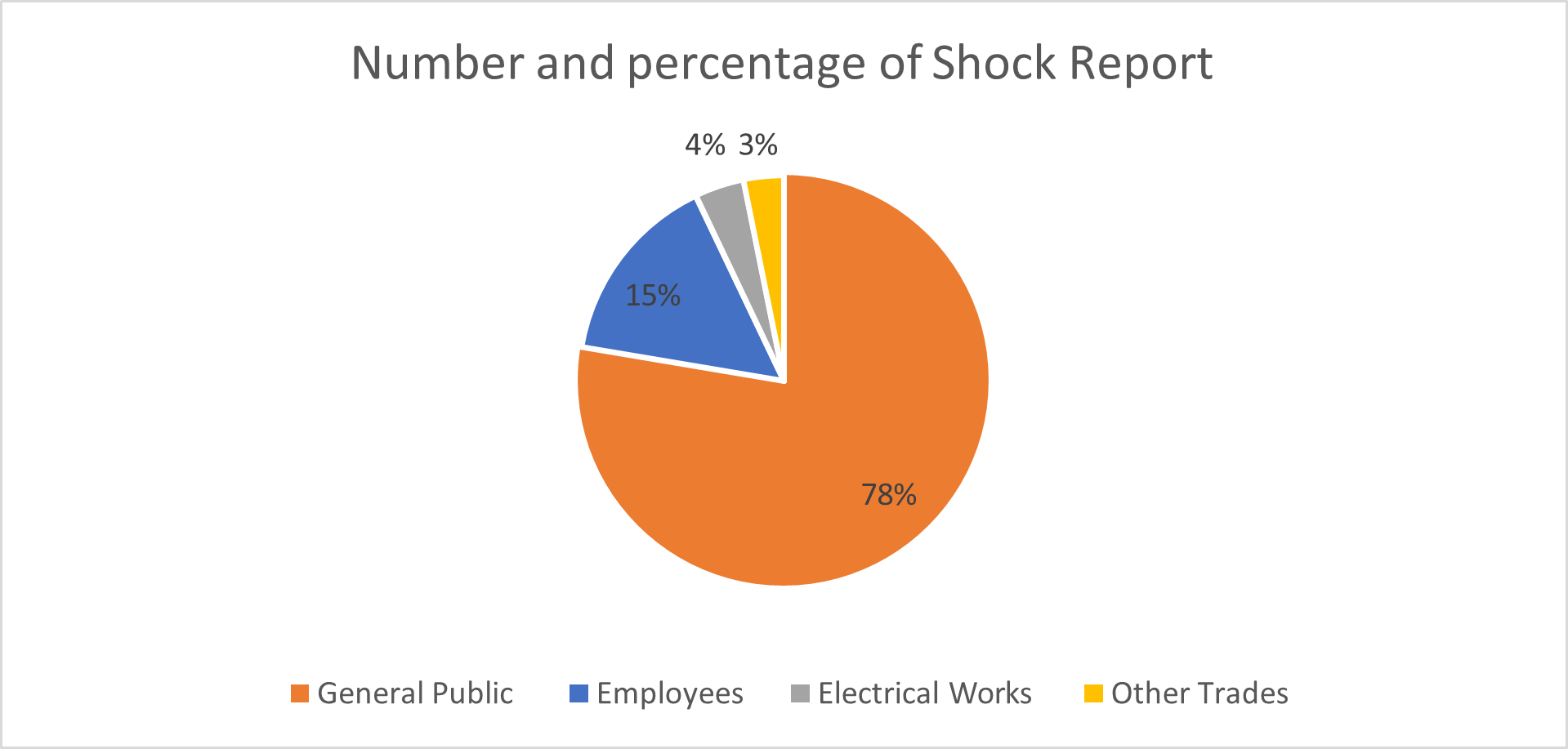

Figure A1 E 4: Shock Report for 2022-2023 by Recipient Category

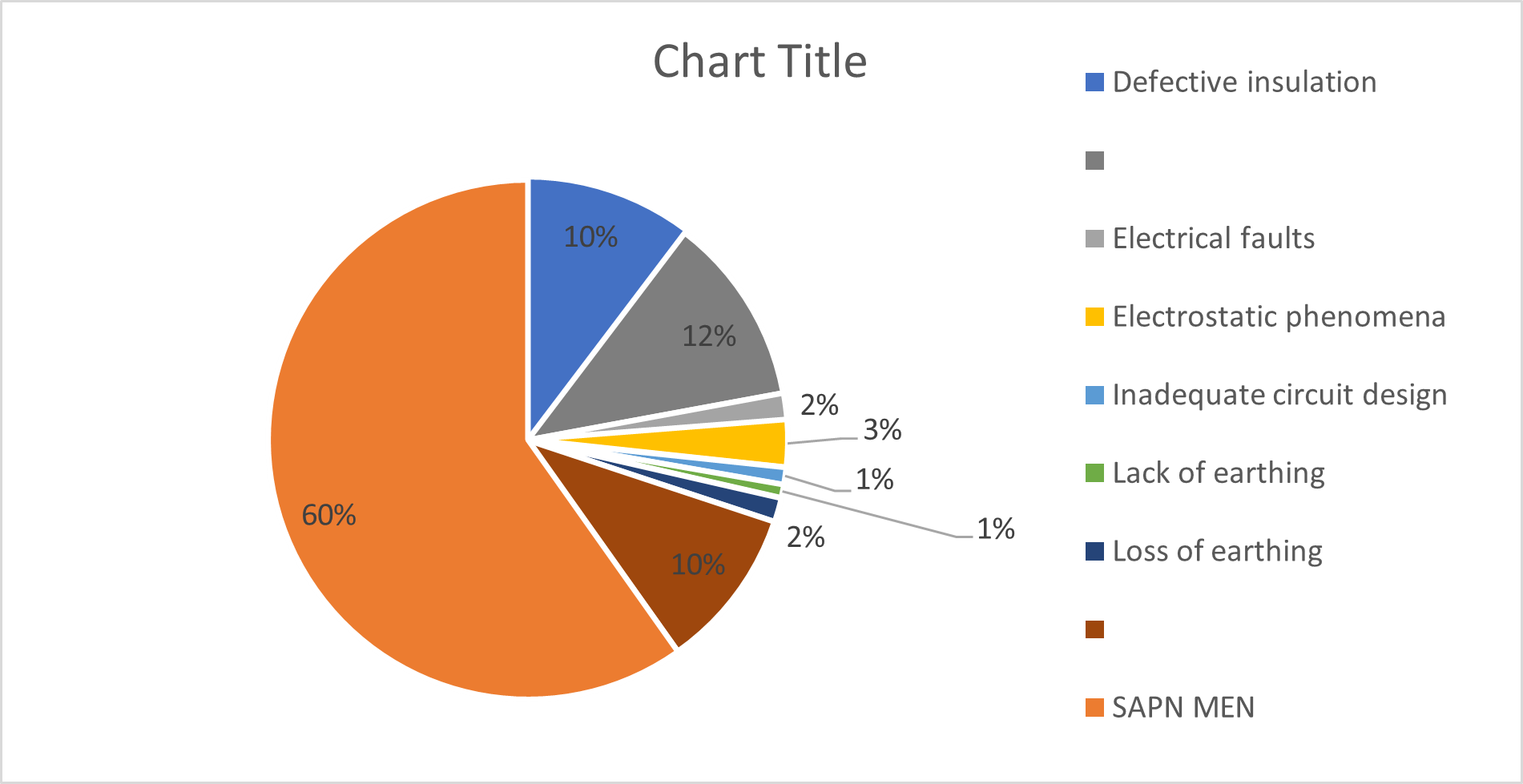

Figure A1 E 5: Shock Report for 2022-2023 by Translated Cause Category

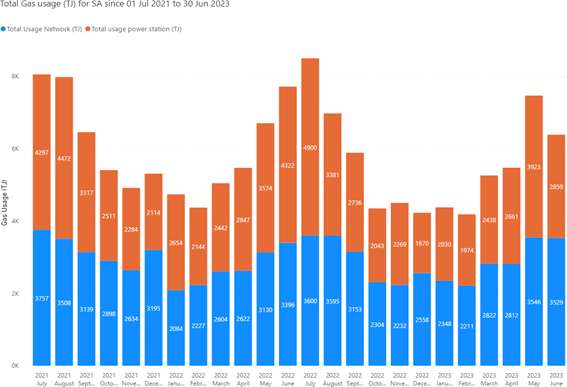

Figure A1 G 1: Total gas usage and usage for power generation in 2021-2022 and 2022-2023

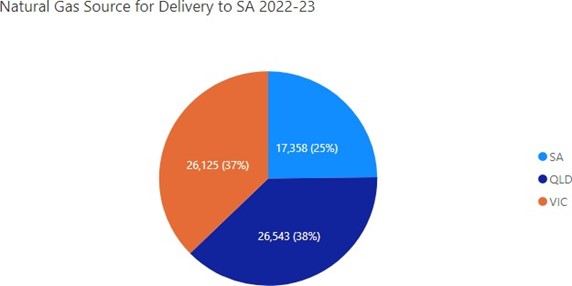

Figure A1 G 2: Natural gas delivered to the SA in 2022-2023

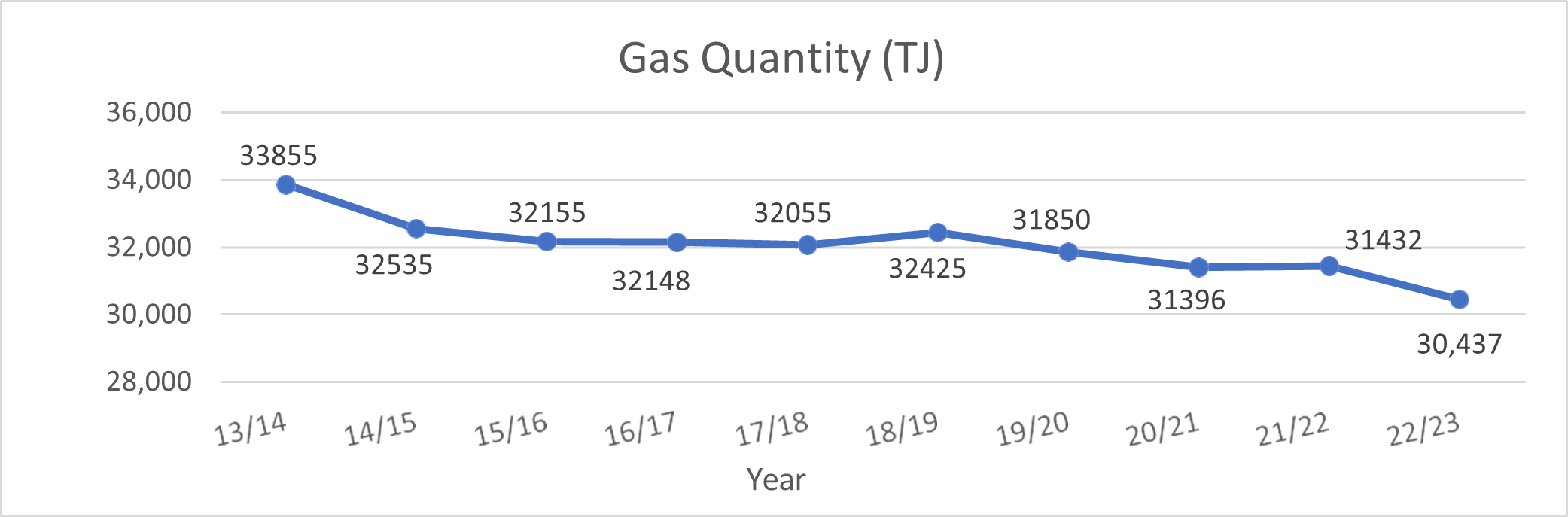

Figure A1 G 3: Trend in the quantity of gas entering the distribution system over the last 10 years

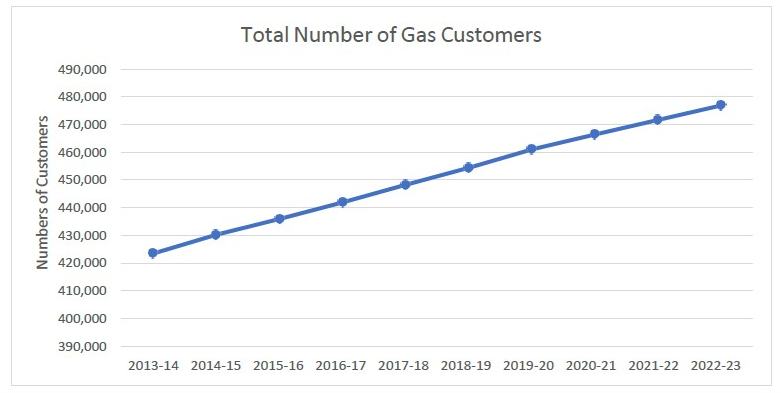

Figure A1 G 4: Numbers of consumers in the natural gas distribution networks over the past 10 years

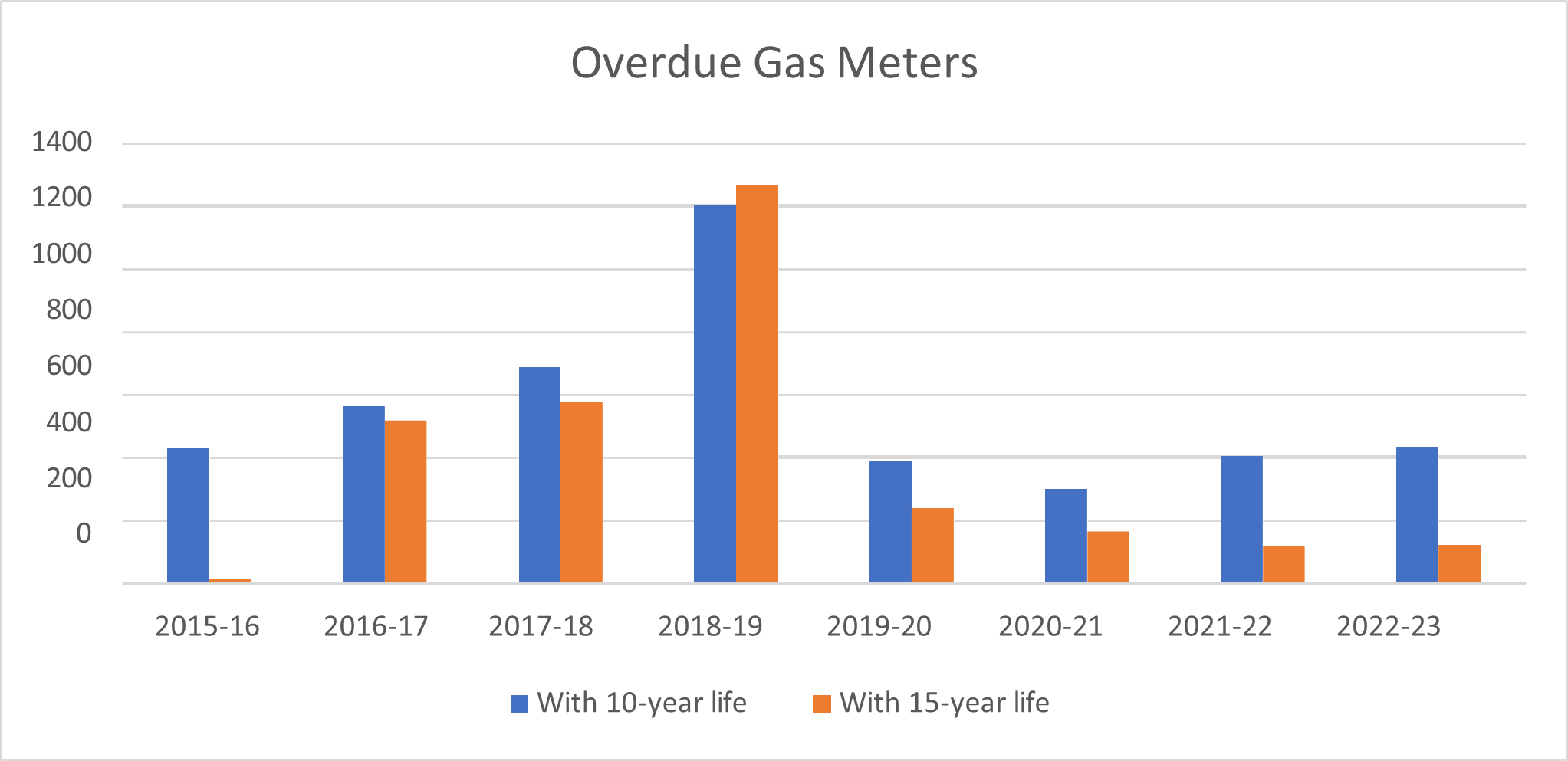

Figure A1 G 5: Overdue gas meters over the past 8 Financial years

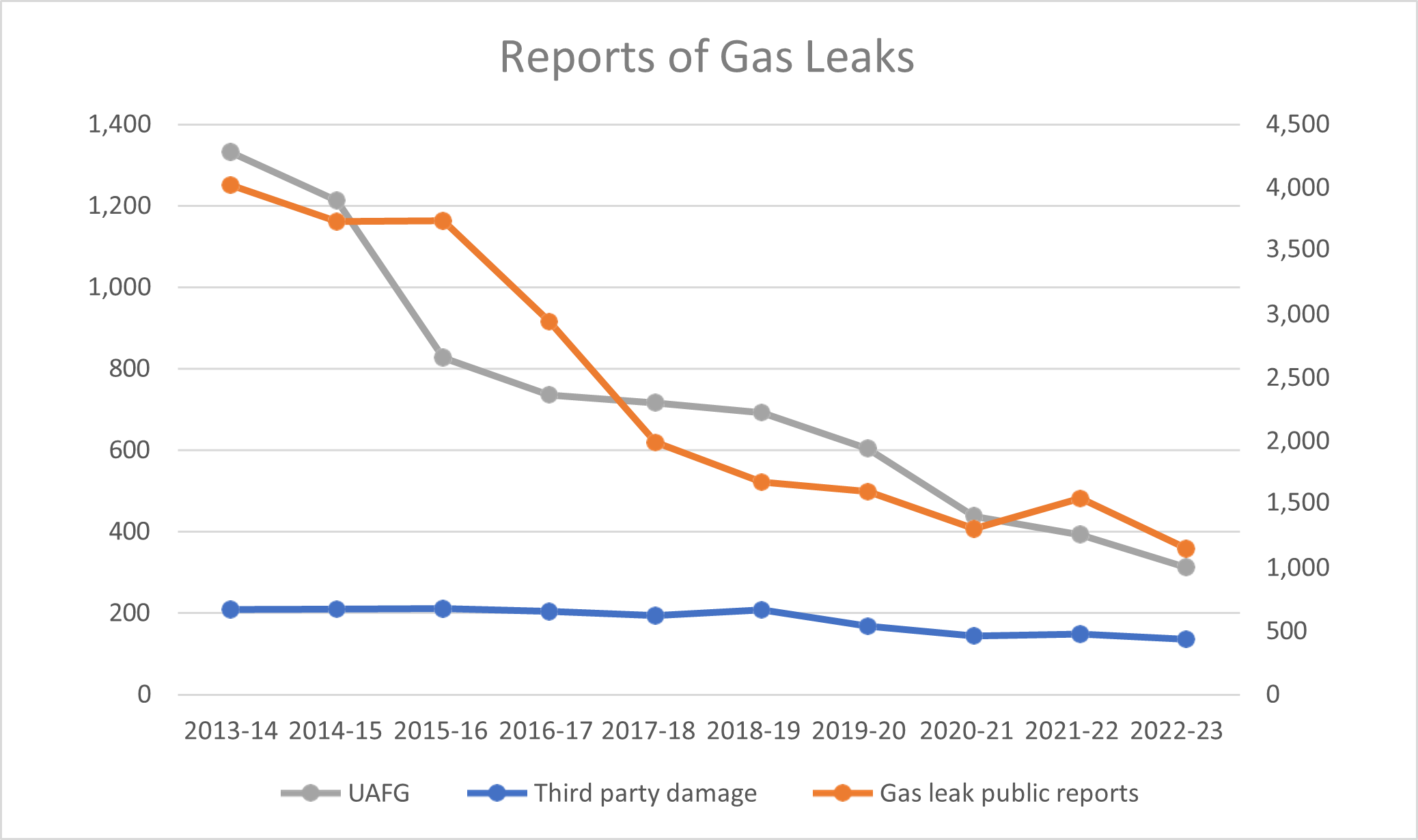

Figure A1 G 6: Numbers of public reports of gas leak and UAFG

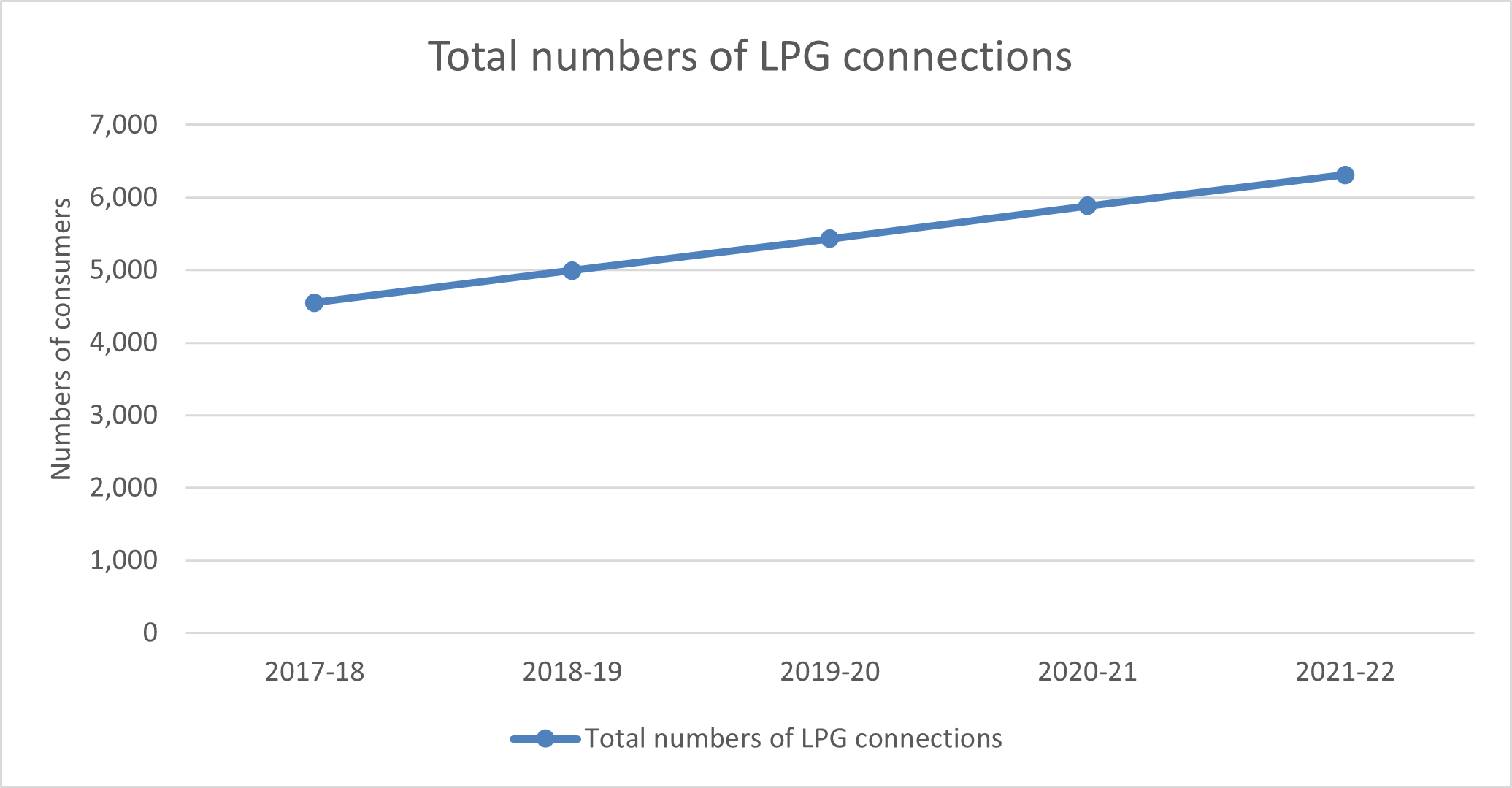

Figure A1 G 7: Total numbers of LPG consumers over the past 5 financial years

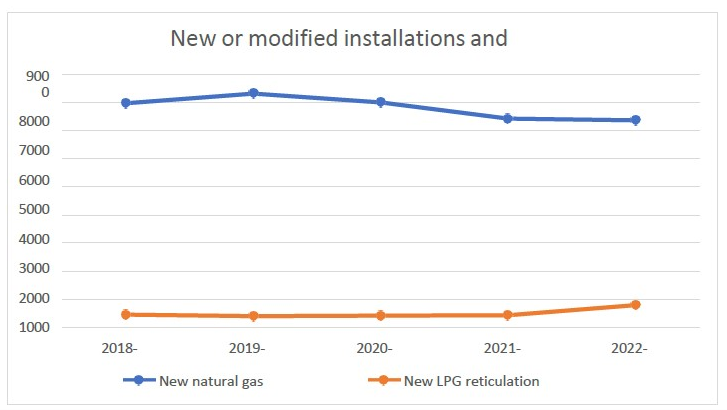

Figure A1 G8: New natural gas connection and reticulation LPG connection the past 5 years

Figure A1 G 9: Bolivar Power Station

Figure A1 G 10: Thomas Foods Industries

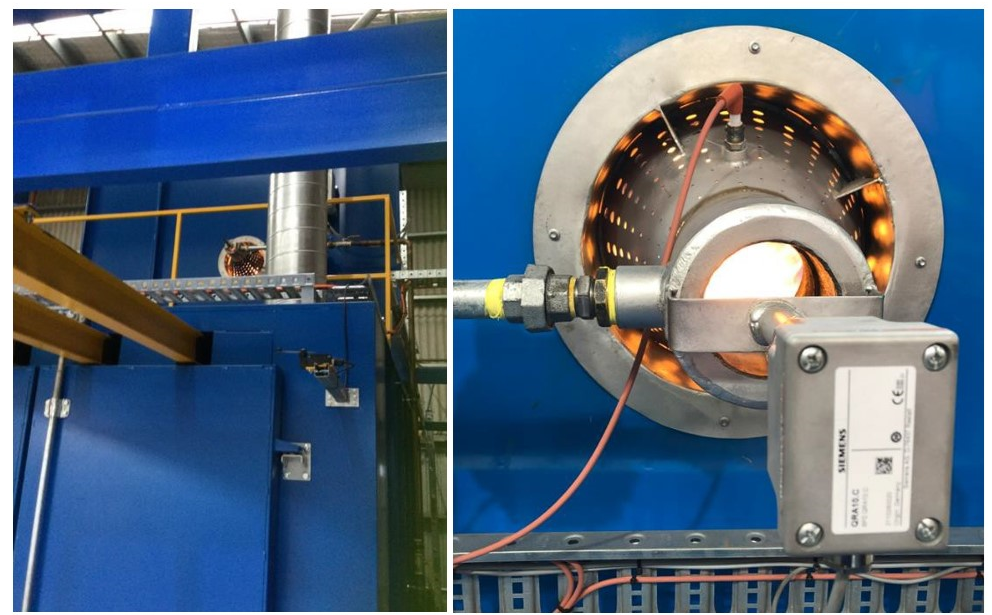

Figure A1 G 11: Photo of a Type B powder coat oven

Figure A1 G 12: Photo of a Type B steam boiler

Figure A1 G 14: Failed outlet service

Figure A1 G 15: Non-compliant HWS location

Figure A1 G 16: Non-compliant installation appliance not commissioned

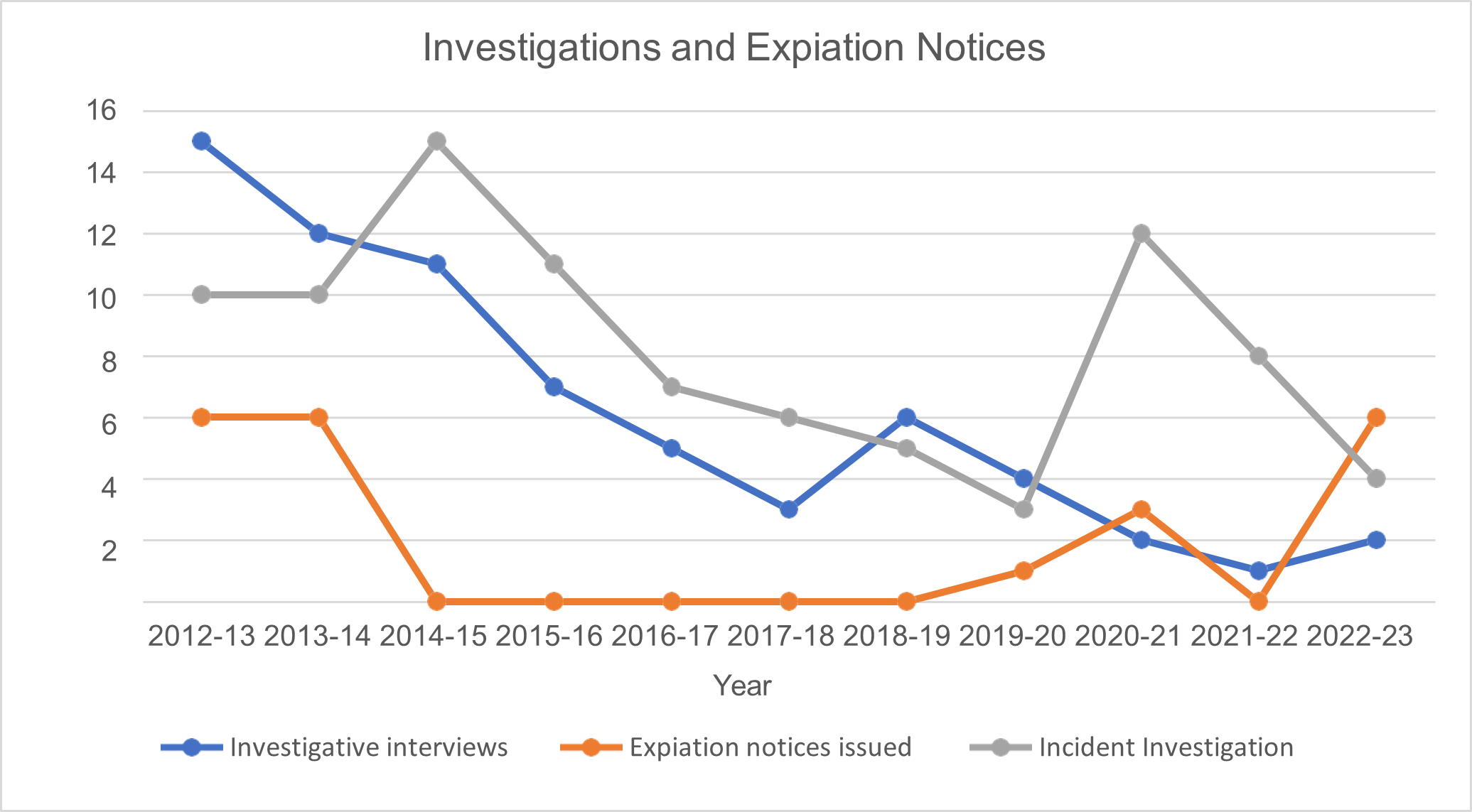

Figure A1 G 17: Investigations and Expiation Notices

Figure A1 G 18: Rotary salt dryer involved in incident

Figure A1 G 19: Deep fryer and open-end hose assembly involved in explosion incident

Figure A1 G 20: Recreational outdoor model water heater involved in explosion incident

Figure A1 G 21: Outdoor portable wok burner and damaged POL connector involved in explosion incident

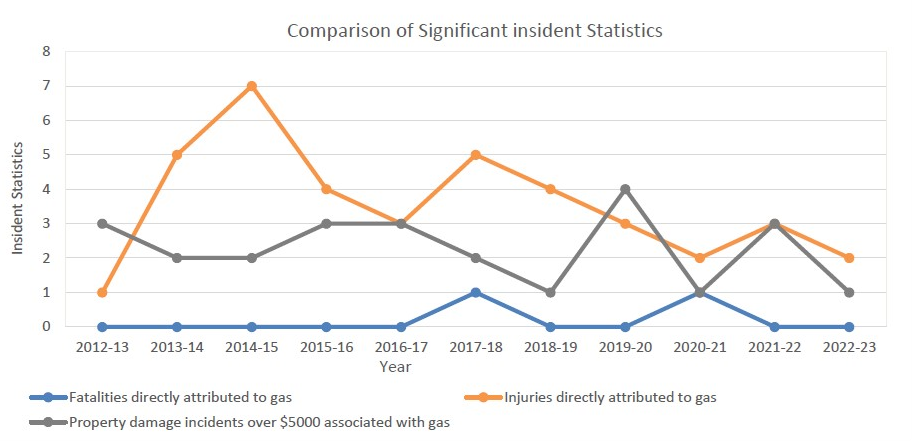

Figure A1 G 22: Comparison of Significant Incident Statistics

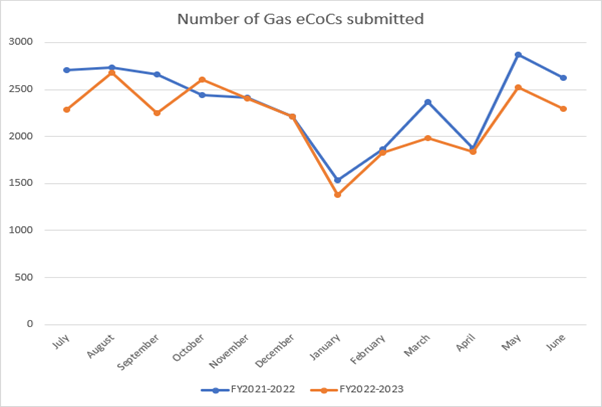

Figure A1 G 23: Gas electronic certificate of complaint submitted over the last two financial year

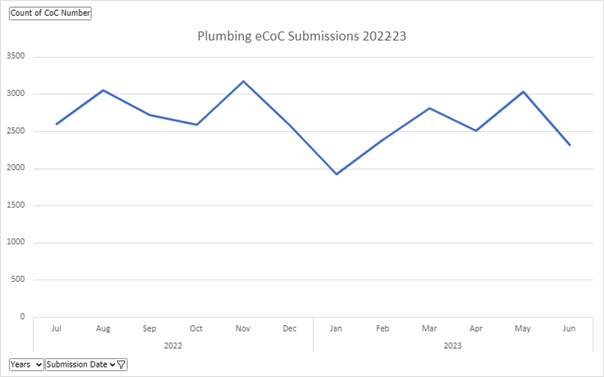

Figure A1 W 1: Plumbing Certificates of Compliance statistics

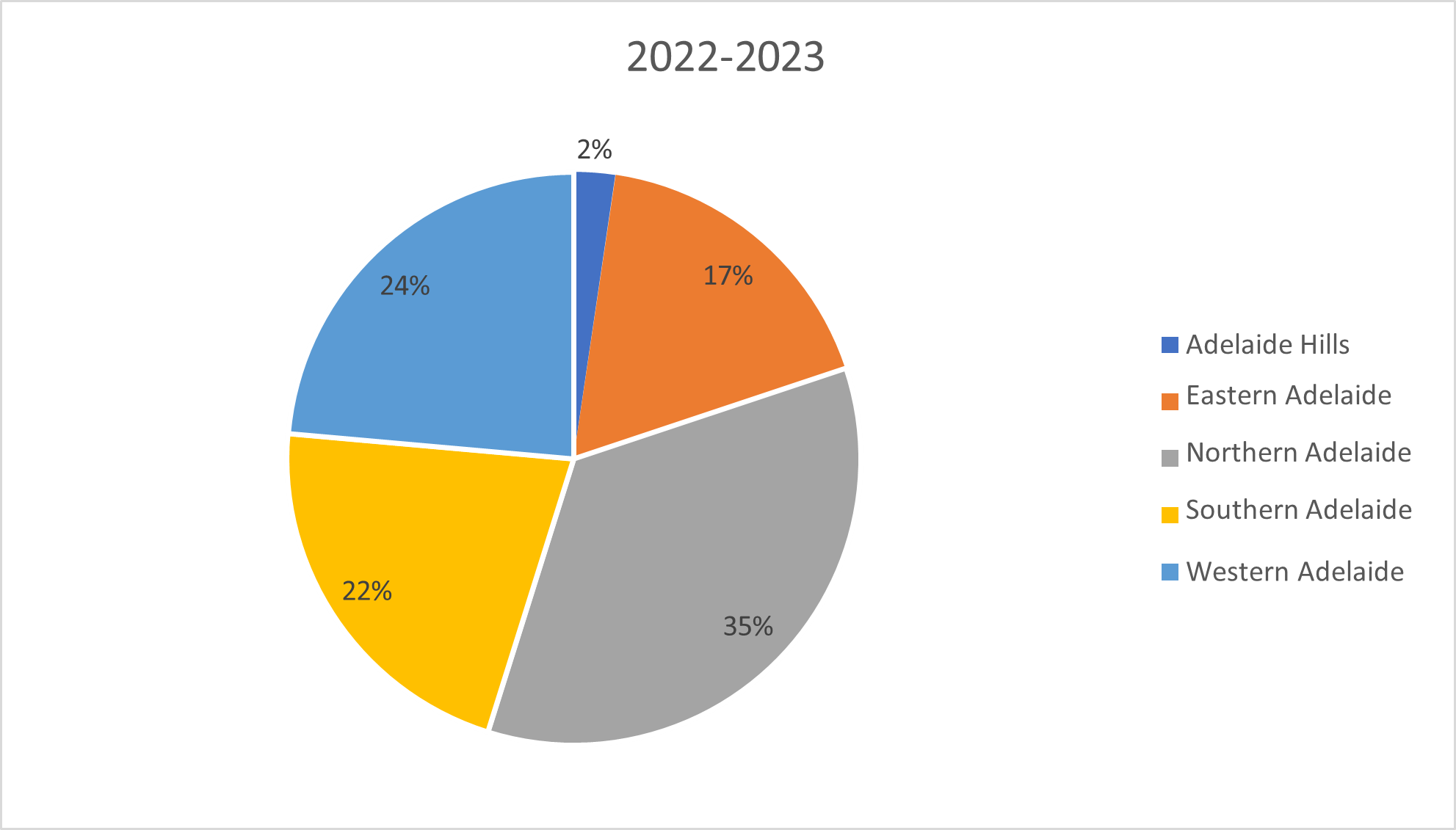

Figure A1 W 2: Metropolitan on-site plumbing installation audits for 2022-2023

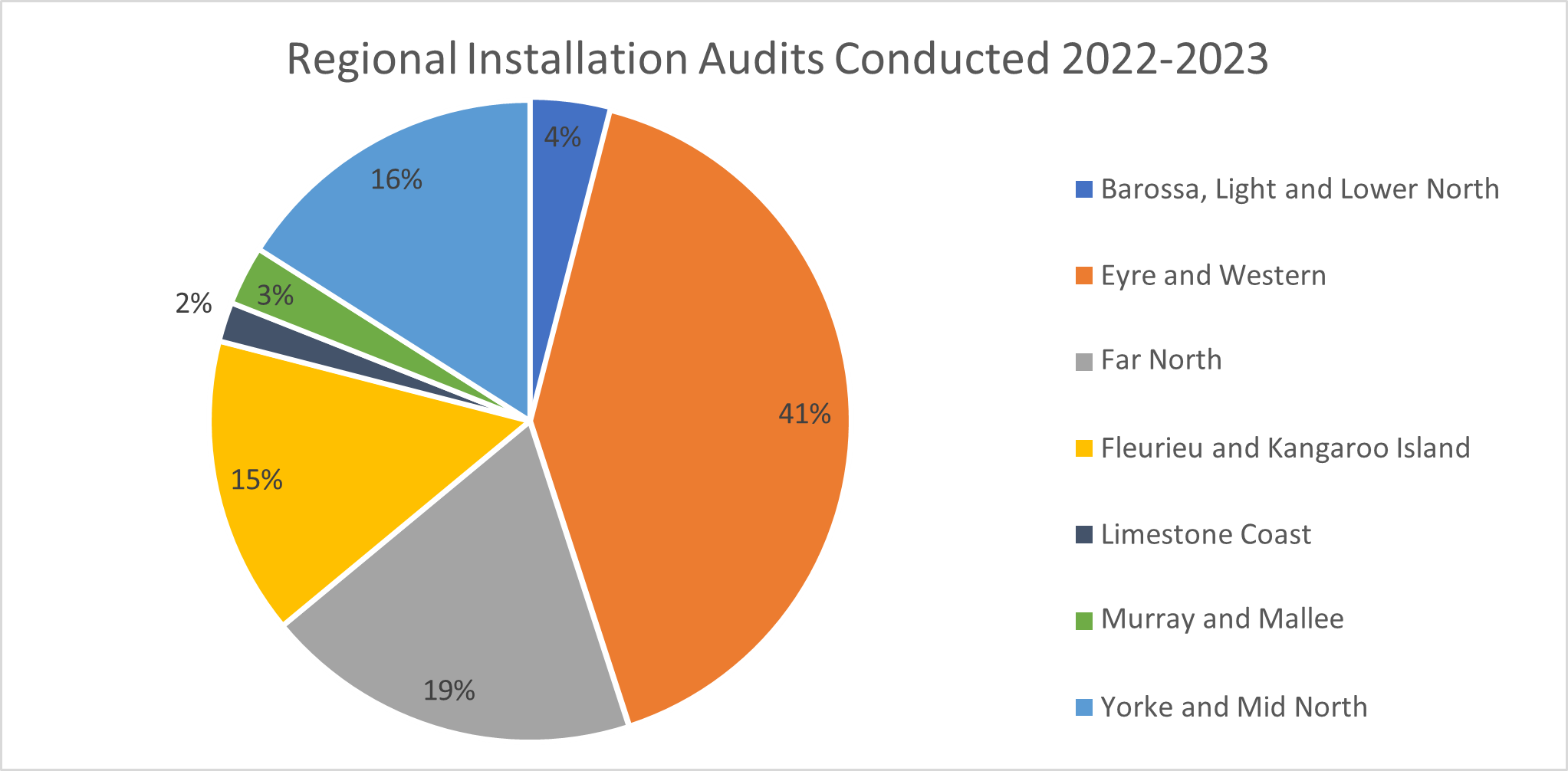

Figure A1 W 3: Regional on-site plumbing installation audits for 2022-2023

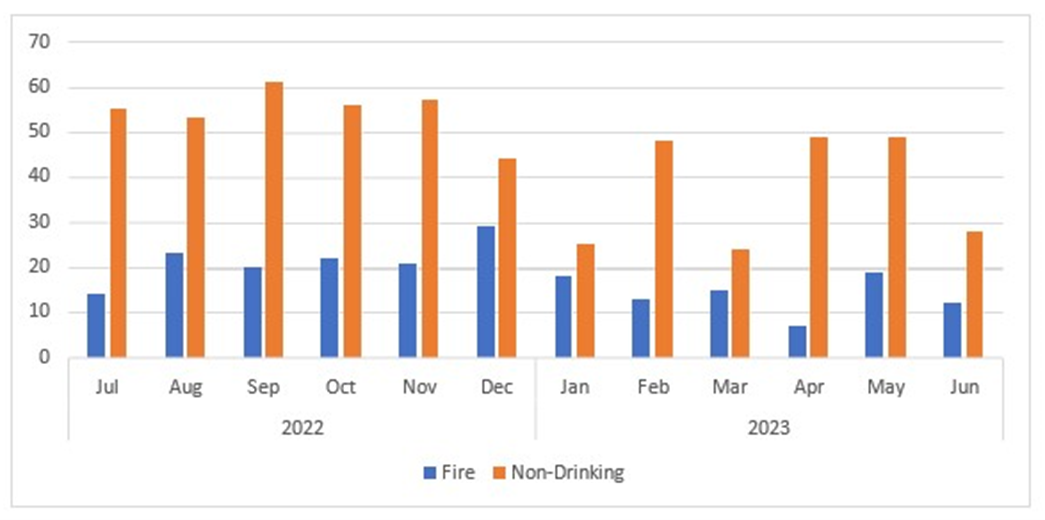

Figure A1 W 4: Fire service and non-drinking water audits for 2022-2023

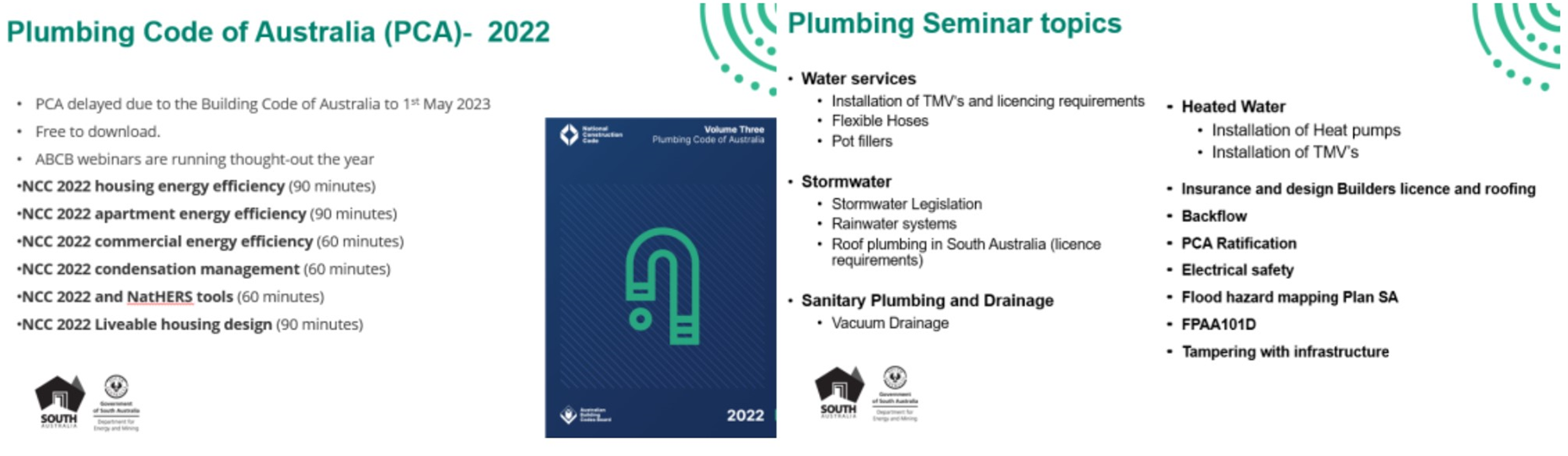

Figure A1 W 5: 2023 Roadshow Seminar Topic

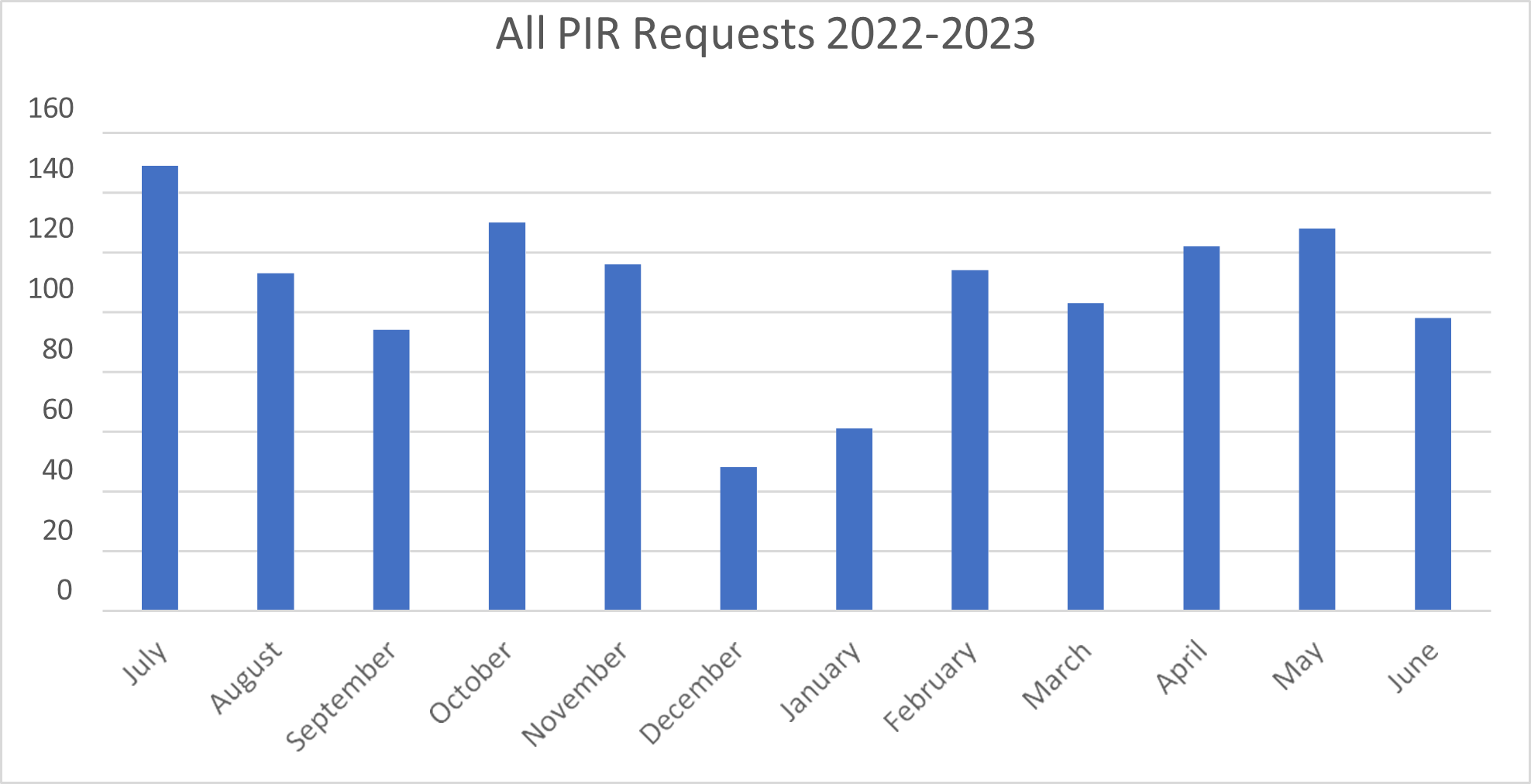

Figure A1 W 6: PIR monthly statistics for 2022-2023

List of Tables

Table E 1: Scheduled Generation with nameplate capacity exceeding 50 MW operation in 2022-23

Table E 2: Grid scale energy storage facilities with a capacity exceeding 20MW

Table E 3: Semi-Scheduled and Non-Scheduled renewable Generation with capacity exceeding 20 MW

Table E 4: ElectraNet transmission network length

Table E5: Distribution network length at May 2023

Table G 1: LPG distribution networks in South Australia as of 30 June 2023

Table W 1: Licence classifications

Table W2: Water industry entities per region in South Australia

Table A1- 1: Electronic Certificates of Compliance statistics as of 30 June 2023

Table A1 E 1: Numbers and Percentage of Shock Report by Recipient Category

Table A1 E 2: Numbers and Percentage of Shock Report by Translated Cause Category

Table A1 G 1: Overview of natural gas delivered to the South Australia

Table A1 G 2: Overview of natural gas delivered to the State

Table A1 G 3: Annual quantity of gas entering AGN’s SA networks (including Farm Taps)

Table A1 G 5: Overdue Gas Meters in 2020-2021, 2021-2022 and 2022-2023

Table A1 G 6: Data reported by the APA group over the last five financial years

Table A1 G 7: LPG distribution networks under development in South Australia

Table A1 G 8: New or modified installations and connections

Table A1 G 9: Results of installation auditing

Table A1 W 1: Number of SRMTMPs received, reviewed and approved

Table A1 W 2: Number of audits undertaken in per type of services

Table A1 W 3: Number of audits undertaken per type of licence

Table A1 W 4: On-Site Plumbing Audits 2022 – 2023

Table K 1: ElectraNet Key Performance Indicators

Table K 2: SA Power Networks Key Performance Indicators

Table K 3: APA Group’s Key Performance Indicators

The Office of the Technical Regulator

General Activities of the Office of the Technical Regulator

Overall Activities

Section 1: Overall Background

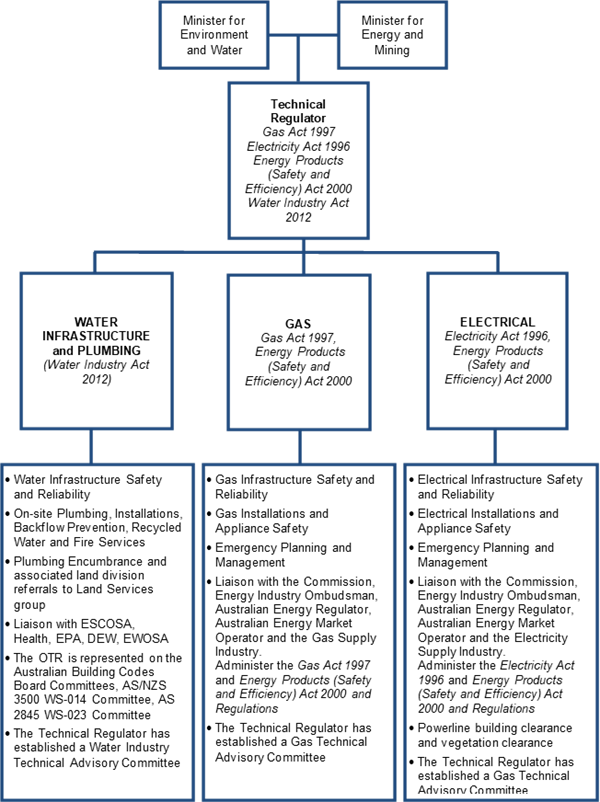

The Office of the Technical Regulator (OTR) assists the Technical Regulator in the performance of his functions and the exercise of his powers under the Electricity Act 1996, the Gas Act 1997 and the Water Industry Act 2012 (the Acts).

The Technical Regulator is responsible to the South Australian Government for the safety and technical performance of the electrical, gas, and water industries. The Technical Regulator also works towards ensuring community safety by promoting and enforcing safety measures and Standards across electrical, gas and plumbing appliances, installations, and infrastructure. To fulfil this responsibility, the Technical Regulator carries out an extensive range of activities, including but not limited to providing technical and safety education and advice, incident inspection and investigation activities and audit activities.

The Technical Regulator plays an important role in the development and monitoring of applicable state and national safety and technical Standards and Codes. The Technical Regulator provides technical support and advice on issues to the relevant Ministers and facilitates discussions with industry stakeholders to achieve the best possible outcome for South Australia.

Appendix 1 of the document presents specific results achieved during the last financial year. The flow chart in Appendix 2 summarises the activities through which the Technical Regulator fulfils his obligations under the various Acts and Regulations.

Section 2: Technical and Safety Regulation

The technical and safety regulation regime is in accordance with the Acts and includes the following components.

2.1. Technical Review of Infrastructure Licence Applications

The Essential Services Commission of South Australia (the Commission) licenses entities under the Acts, and provides the following licences:

- A licence authorising the generation of electricity or the operation of a transmission or distribution network.

- A licence authorising the operation of a gas distribution system.

- A licence authorising the provision of water and/or sewerage retail services.

Entities that have applied for and received a licence exemption may not be exempted from their responsibilities to the Technical Regulator under the Acts.

All licensing requirements can be found on the Commission’s website. Licence applications to the Commission must include organisational, commercial, and technical information. Technical information is referred to the Technical Regulator for review, and a response is provided to the Commission for consideration during their licence application assessment.

2.2. Safety, Reliability, Maintenance and Technical Management Plan

The Technical Regulator may or will, depending upon the Act, require the entities licensed by the Commission to prepare and periodically revise a Safety, Reliability, Maintenance, and Technical Management Plan (SRMTMP).

A SRMTMP is a high-level document relating to safety and technical requirements and which defines key performance indicators to measure the actual performance of an entity. It provides an auditable quality approach to industry safety and technical performance, encouraging the continuous improvement of safety systems and technical compliance.

The SRMTMP addresses issues relating to the technical Standards, operating and maintenance procedures and management practices, including safety requirements, applicable to an entity. The SRMTMP demonstrates how the entity will comply with the direct requirements of the legislation as well as the Standards and Codes called up by the legislation.

The overall information that a SRMTMP must address is defined in the Electricity (General) Regulations 2012, the Gas Regulations 2012, and the Water Industry Regulations 2012 (the Regulations). Guidance documents and general information for preparing SRMTMPs are also available on the OTR website to assist entities.

The Technical Regulator reviews an entity’s SRMTMP and, where appropriate, provides direction and makes recommendations or comments to assist in refining it before its final approval. The Technical Regulator is directly responsible for the approval of the SRMTMP for the three industries: electricity, gas, and water.

2.3. Audits of Compliance

2.3.1. Infrastructure internal audits

Following the submission and subsequent approval of a SRMTMP, an entity must complete annual internal audits which confirm compliance with its SRMTMP. Those internal audits can be completed by the entity itself or by a third party. Any findings from the internal audits are reported to the Technical Regulator for review and comments.

Once the Technical Regulator is satisfied that the entity has addressed all identified issues and complied with its SRMTMP, the entity then updates the plan to include required changes identified in the audit and any recommendations from the Technical Regulator.

2.3.2. Infrastructure audits by the Technical Regulator

In addition to the entity’s annual internal audits, the Technical Regulator completes independent safety and technical audits to verify the accuracy of information provided in, and compliance with, an entity’s SRMTMP. These audits ensure that safety and technical Standards are maintained in the electrical, gas and water industries by confirming that:

- Appropriate systems and processes have been developed.

- Compliance with these systems and processes is maintained.

- The systems and processes comply with entity’s current approved SRMTMP.

The Technical Regulator conducts both field and desktop audits to confirm that the entity is operating in accordance with its policies and procedures which ensure the safe and reliable operation of the infrastructure. Upon completion of an audit, the Technical Regulator provides the entity with a report of observations and provides comments and/or recommendations.

Audits completed by the Technical Regulator also allow for the monitoring of technical safety and reliability trends within the electrical, gas and water industries and comparison to other National and Global industries.

2.3.3. Installations compliance audit

The Technical Regulator has a process in place whereby electrical, gas and plumbing domestic, commercial, and industrial installations are monitored for compliance with the Acts, Regulations, and relevant Standards.

Periodic (seasonal, recurring, and ongoing) events are monitored to ensure the safety of the public and workers at the event in relation to the temporary and permanent electrical, gas and plumbing equipment and installations. This is often done in conjunction with other relevant Authorities such as SafeWork SA or Consumer and Business Services.

2.4. Incidents Investigations

2.4.1. Infrastructure incidents

Infrastructure incidents that involve death, injury to a person which requires medical assistance, property damage or any critical infrastructure failure must be reported to the Technical Regulator under the Electricity Act 1996 and the Gas Act 1997. Water infrastructure incidents shall also be reported to the Technical Regulator under a specific incident protocol. Incident reports are recorded by the Technical Regulator and, where appropriate, the incidents are investigated.

During major consumer outages and incidents, the Technical Regulator monitors the outage and assesses the adequacy of the response. This provides a level of confidence that the operational and maintenance strategy employed by the service providers is effective.

2.4.2. Installation incidents

Installation incidents are where an appliance or its installations is directly attributed to the cause of human death, injury or property damage. The Regulations require these events to be reported within specific time frames depending on severity.

These events are investigated by the Technical Regulator to determine the cause, often in conjunction with other relevant authorities or organisations, such as the Metropolitan Fire Services (MFS), Country Fire Service (CFS), SA Police (SAPOL), SafeWork SA, and insurance companies. Incidents reported to the Technical Regulator are investigated and recorded. OTR personnel may be called as witnesses in any subsequent legal action.

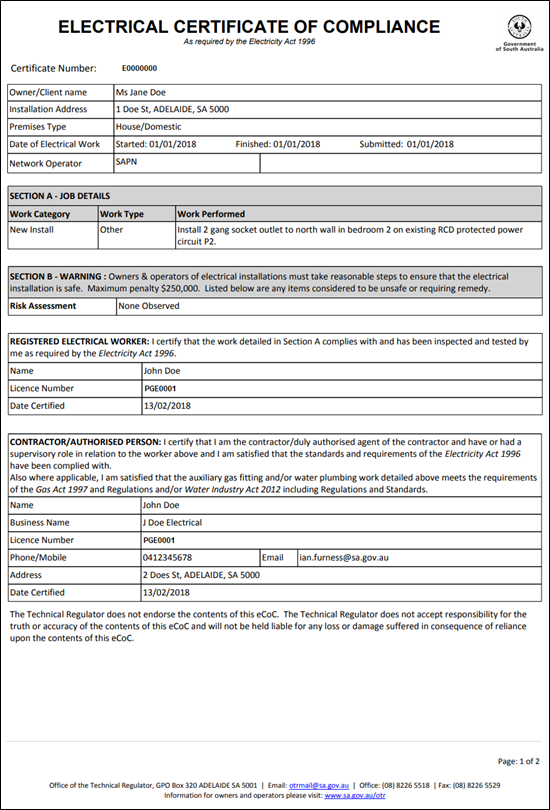

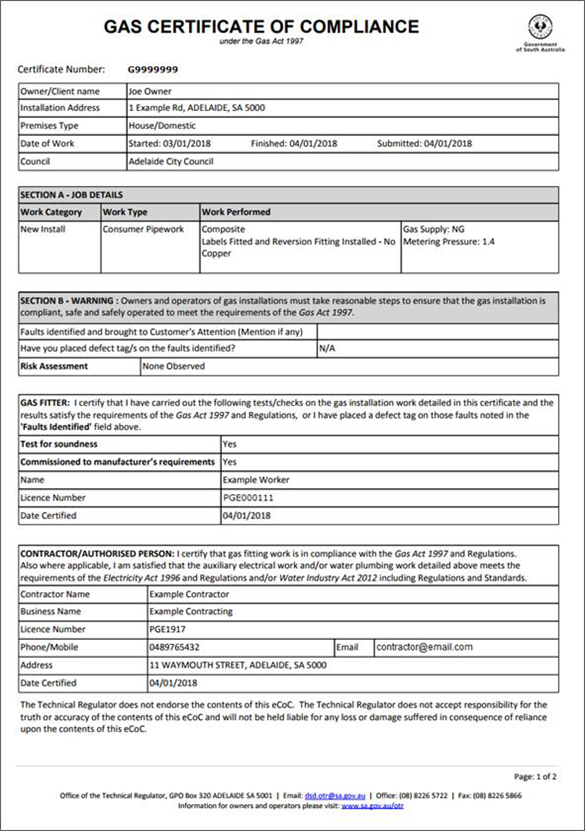

2.4.3. Electronic Certificate of Compliance

Certificates of Compliance are provided to property owners by an appropriately licensed person to demonstrate that they have met their duty to ensure that the electrical, gas fitting or plumbing works completed at their property is compliant. See Appendix 3 for an example of an electrical, gas and plumbing electronic Certificate of Compliance. The purpose of the certificate is to:

- Enable self-certification of work.

- Describe the works that have been completed.

- Assure the customer that the work is installed and tested to the appropriate Standard.

- Protect the licensed person by confining the responsibilities to the work that they have carried out.

- Allow the Technical Regulator to audit installations for adherence to safety and technical Standards.

The OTR has transitioned from the previous paper-based process for electrical, gas and plumbing Certificates of Compliance to an automated electronic system called electronic Certificates of Compliance (eCoC).

The eCoC system is free for electrical, gas and plumbing contractors and workers, and enables them to complete, submit, store and refer to Certificates of Compliance online. Contractors and workers can access the eCoC system via the internet from desktop and mobile devices. A one-time registration needs to be completed to use the eCoC system. Contractors and workers need to provide a professional registration/licence number and expiry date as well as an email address, a password and contractor/worker details.

Overall, the system is considered more flexible, being on a digital form, and more professional, with continuous improvements are brought to the platform based on the feedback received from users. Any feedback on the system can be sent to otr.ecoc@sa.gov.au.

More information and updates on the eCoC project can be found on the OTR eCoC website.

2.5. Technical Advisory Committees

Under the Acts, the Technical Regulator must establish an advisory committee (technical advisory committee) for each industry, including representatives of industry entities, contractor and employee associations involved in the industry, and local government.

The objective of these committees is to provide advice to the Technical Regulator, either on their own initiative or at the request of the Technical Regulator, on any matter relating to the functions of the Technical Regulator.

Section 3: Participation in Standards

The Technical Regulator is actively represented on several Australian Standards and joint Australian and New Zealand Standards Committees, the Australian Building Codes Board’s Plumbing Code Committee and International Standards. Committees relate to electrical, plumbing and gas products, design, installation and commissioning of electrical installations, gas installations, on-site plumbing installations, and design, operations, and maintenance of electrical, gas and water infrastructure.

Section 4: Emergency Management

The Technical Regulator works closely with relevant emergency management stakeholders to assist in ensuring the resilience of the State in case of an energy emergency, including the State Emergency Management Committee, SA Police, the Australian Energy Market Operator (AEMO) and major SA energy entities. When required, the OTR has several staff members available to be rostered with the State Emergency Centre (SEC) to provide electricity, gas and fuel supply monitoring and engineering service advice during a state emergency.

The Technical Regulator plays a key role in the monitoring of the security of the power system in South Australia. The Technical Regulator works with the Bureau of Meteorology (BOM), and stakeholders within the electricity generation, transmission and distribution industries, to ensure that appropriate precautions are taken during times when there is a risk to the power system (i.e. large storm systems, bushfires, extreme temperatures, etc).

During times when the load in South Australia may not be forecast to be balanced by electricity generation, the Technical Regulator may seek voluntary load reduction from large energy users across several industries. The Technical Regulator also manages the South Australian Electricity Manual Load Shedding List (the list) in cooperation with SA Power Networks as the distribution network service provider, ElectraNet as the transmission network service provider, and AEMO as the electricity market operator.

The list sets out the electrical circuits which should be tripped if AEMO instructs to reduce load to maintain the power system’s security and integrity. The preparation of the list is an obligation on the Technical Regulator under the National Electricity Rules in his role as the Jurisdictional System Security Coordinator for South Australia.

The Technical Regulator also has the responsibility to assess and monitor any threatening situations in relation to gas supply and is required to manage an emergency where societal objectives can no longer be met by the market. Should an event occur, normally the Short-Term Trading Market (STTM) for gas would be the first line of defence in managing any shortfall. The STTM is operated by AEMO and sets a daily price at each gas hub. It runs once a day, for the day ahead, for each hub. It utilises bids, offers, and forecasts as submitted by the participants and the pipeline capacities to determine the schedules for the deliveries of gas. The STTM also operates a contingency gas market should gas supplies fall short of the estimated daily demand.

The use of the contingency gas market will extend the use of market outcomes. AEMO may also implement the Gas Supply Guarantee process to make gas available to meet peak demand periods in the National Electricity Market. If the shortfall is not resolved, the Technical Regulator would consider recommending that the Minister issue directions for temporary gas rationing.

Section 5: Consumer Safety Awareness

5.1. Assistance with the Development of Technical Training Courses

The Technical Regulator continues to liaise closely with Consumer and Business Services (CBS), TAFE SA and PEER Vocational Education, Employment and Training (VEET) about tradespeople training curriculums and competencies (CBS regulates the licensing of tradespeople under the Plumbers, Gas Fitters and Electricians Act 1995).

Tailored safety presentations are given to apprentice groups at registered training organisations across the State. Presentations are also given to other groups such as professional associations and contractor groups on request.

5.2. Industry Roadshows

A key initiative of the OTR is Industry Roadshows where presentations are provided to electrical, gas and plumbing workers and contractors across South Australia.

Roadshows are provided at all major population centres annually, and other regional areas less frequently, such as bi-annually, and are typically held in conjunction with industry associations. Roadshows provide an opportunity to share updates in electrical, gas and plumbing Standards and legislation, and obtain feedback from the industry.

5.3. Regulation Roundup

To keep the electrical, gas and plumbing industry informed, the Technical Regulator publishes a bi-annual joint electrical/gas/plumbing industry newsletter – Regulation Roundup. Regulation Roundup is dispatched electronically to contractors and workers.

Figure 1: Example of Regulation Roundup

5.4. Continuous Safety Promotion

5.4.1. Proactive awareness campaign

The ‘Be Energy Safe’ Campaign is facilitated by the Technical Regulator and reviewed annually. Its objective is to promote safety to the community by raising awareness of electrical, gas, and plumbing safety and influencing the public to take the appropriate actions. The campaign involves the provision of messages which are promoted via advertising on the rear of public transport buses, on social media and during traffic reports on the radio.

Previous key messages included:

- Carbon monoxide (CO) awareness – do not bring outdoor gas appliances indoors – service your appliance regularly.

- Gas leaks should be reported via the Gas Emergency and Leak Reporting Service on 1800 GAS LEAK (1800 427 532).

- Plumbing, gas and electrical jobs should be done by a licensed person – not DIY.

- Plumbing, gas and electrical works should come with a Certificate of Compliance.

- Barbecues should be serviced regularly to prevent gas leaks.

- A safety switch should be tested twice a year.

- Christmas lights should be checked for faults prior to being used.

- Avoid scalding from hot water.

The campaigns are published by an advertising company and performance reports are provided regularly to the Technical Regulator to monitor the rate of penetration of the advertisements. Overall, the campaign is considered to achieve fair results. Some examples of the advertisements are shown in the figure below.

Figure 2: Example of safety awareness campaign advertisements

5.4.2. Reactive awareness campaign

Reactive safety awareness campaigns are undertaken by the Technical Regulator and usually take the form of a single or series of media releases around the topic of interest. Typically, this type of campaign is the result of an incident and ensures that the public receives correct and appropriate safety information.

5.4.3. OTR’s Website

The OTR’s website includes current content on technical regulation and safety issues at:

- All technical information for Office of the Technical Regulator | Energy & Mining (energymining.sa.gov.au)

- Consumer information for gas, electricity and hot water safety.

5.5. Consumer Safety Survey

Every year, the Technical Regulator conducts a consumer safety survey to ascertain the public’s knowledge of gas and electrical safety, and the effectiveness of the OTR’s education campaigns and legislative functions. The survey is performed by an external contractor using computer assisted telephone interview and online surveys. Over the last three years, approximately 400 online surveys were conducted, with two-thirds located in the Adelaide metropolitan area and one-third in SA regional areas. Questions used for the survey remain consistent to provide comparisons to previous results.

Section 6: Energy and Water Ombudsman SA

There is a Memorandum of Understanding (MOU) in place between the Technical Regulator and the Energy and Water Ombudsman SA (EWOSA). The MOU defines how the two bodies will interact to deal with customer complaints.

The EWOSA seeks the Technical Regulator’s advice on some occasions. Advice may be sought on customer complaints received by the EWOSA that has resulted from the customer not being satisfied with the responses from the electricity entities. The technical input provided by the Technical Regulator assists the EWOSA in assessing a range of complex issues.

Volume I – Electricity Industry Preface

This volume covers the Technical Regulator’s operations under the Electricity Act 1996 and the Technical Regulator’s administration of the Energy Products (Safety and Efficiency) Act 2000.

Electricity Act 1996

Section 3 of the Electricity Act 1996 states that:

“The objects of this Act are—

(a) to promote efficiency and competition in the electricity supply industry; and

(b) to promote the establishment and maintenance of a safe and efficient system of electricity generation, transmission, distribution and supply; and

(c) to establish and enforce proper standards of safety, reliability and quality in the electricity supply industry; and

(d) to establish and enforce proper safety and technical standards for electrical installations; and

(e) to protect the interests of consumers of electricity.” Section 8 of the Electricity Act 1996 states that:

“The Technical Regulator has the following functions:

(a) the monitoring and regulation of safety and technical standards in the electricity supply industry; and

(b) the monitoring and regulation of safety and technical standards with respect to electrical installations; and

(c) the administration of the provisions of this Act relating to the clearance of vegetation from powerlines; and

(ca) the monitoring and investigation of major interruptions to the electricity supply in the State and the provision of reports relating to such interruptions in accordance with any requirements prescribed by the regulations; and

(d) any other functions prescribed by regulation or assigned to the Technical Regulator by or under this or any other Act.”

Energy Products (Safety and Efficiency) Act 2000

The Energy Products (Safety and Efficiency) Act 2000 makes provisions relating to the safety, performance, energy efficiency and labelling of products powered by electricity, gas or some other energy source.

Section 7: Electrical Infrastructure

7.1. Electricity Supply

7.1.1. Ensuring safety within the Electricity Supply Industry

Public Safety

Public safety is achieved under the Electricity Act 1996 through:

- The prescription of safe distances between powerlines and structures or vegetation.

- The prescription of safe working distances in proximity to powerlines, which vary depending on the voltage of the powerlines, the type of activity being performed, and the risk assessment being considered by the worker.

- The prescription of technical safety.

Safe Work Practices

The safety of electrical workers is regulated by the Work Health and Safety Act 2012. Accidents are required to be reported in accordance with regulation 70 of the Electricity (General) Regulations 2012.

The Electricity Act 1996 and the Electricity (General) Regulations 2012 set out requirements related to the safety of electricity infrastructure, including monitoring through SRMTMPs and also of electrical installations. Safety performance is measured against nationally accepted benchmarks and expressed as:

- Lost Time Injuries – the number of injuries resulting in more than one working day lost.

- Medical Treatment Injuries – the number of injuries requiring medical treatment. Electricity entities provide these indicators as part of their annual reporting to the Technical Regulator.

Live Powerline Work Safety

The Electricity (General) Regulations 2012 prescribe safety procedures and processes to be employed while working on or near live powerlines. A person who wants to perform high voltage live line work must complete an appropriate training course. The content of that course and the training provider must be approved by the Technical Regulator.

Currently, seven training providers have obtained Technical Regulator approval:

- SA Power Networks Skill Enhancement Centre.

- Omaka Training (New Zealand).

- Transgrid.

- Serect — A Subsidiary of Electrité De France (Edf).

- Aeropower Pty Ltd.

- Powerline Training Pty Ltd.

- Enersafe.

Substation Work Safety

Substations are considered high risk areas. Prior to working in a substation, a worker must have the appropriate level of accreditation for access to the required areas and functions in the substations, complete an induction and follow safe access processes including compliance with work permit systems.

7.1.2. Major Generation

In South Australia, the major entities responsible for scheduled generation supply a total installed nameplate capacity of 3077.16 megawatts (MW). Natural gas is the source of fuel for the majority of these generators.

Table E 1: Scheduled Generation with nameplate capacity exceeding 50 MW operation in 2022-23

| Power Station | Fuel | Owner | Capacity (MW) |

|---|---|---|---|

| Angaston | Diesel | Snowy Hydro Ltd | 50 |

| Barker Inlet | Natural Gas Pipeline | AGL Barker Inlet Pty Ltd | 210 |

| Bolivar | Natural Gas Pipeline | Iberdrola Australia Energy Markets Pty Limited | 123.2 |

| Dry Creek GT | Natural Gas Pipeline | Synergen Power Pty Ltd | 156 |

| Hallett GT | Natural Gas Pipeline | EnergyAustralia | 276.86 |

| Ladbroke Grove | Natural Gas Pipeline | Origin Energy Power Limited | 80 |

| Mintaro GT | Natural Gas Pipeline | Synergen Power Pty Ltd | 90 |

| Osborne | Natural Gas Pipeline | Osborne Cogeneration Pty Ltd | 180 |

| Pelican Point | Natural Gas Pipeline | Pelican Point Power Limited | 529 |

| Port Lincoln GT | Diesel | Synergen Power Pty Ltd | 73.5 |

| Port Stanvac 1 | Diesel | Snowy Hydro Ltd | 57.6 |

| Quarantine | Natural Gas Pipeline | Origin Energy Power Limited | 234 |

| Snapper Point | Diesel | Port Adelaide Energy Pty Ltd | 154 |

| Snuggery | Diesel | Synergen Power Pty Ltd | 63 |

| Torrens Island B | Natural Gas Pipeline | AGL Energy | 800 |

| Total | 3,077.16 |

Reference: AEMO: NEM Generation Information July 2023

7.1.3. Energy Storage

South Australia’s generation mix also includes an increasing number of grid scale energy storage facilities.

Table E 2: Grid scale energy storage facilities with a capacity exceeding 20MW

| Power Station | Owner | Capacity (MW) |

|---|---|---|

| Dalrymple BESS | ElectraNet | 30 |

| Hornsdale Power Reserve | Hornsdale Power Reserve Pty Ltd | 150 |

| Lake Bonney BESS | Lake Bonney BESS Pty Ltd | 25 |

| Total | 205 |

Reference: AEMO: NEM Generation Information July 2023

7.1.4. Renewable Generation

South Australia’s generation mix also includes an increasing number of grid scale energy storage facilities.

Table E 3: Semi-Scheduled and Non-Scheduled renewable Generation with capacity exceeding 20 MW

| Power Station | Fuel | Capacity (MW) |

|---|---|---|

| Adelaide Desalination Plant | Solar | 24.72 |

| Bungala One | Solar | 135 |

| Bungala Two | Solar | 135 |

| Canunda Wind Farm | Wind | 46 |

| Cathedral Rocks | Wind | 62 |

| Clements Gap | Wind | 56.7 |

| Hallett 4 North Brown Hill | Wind | 132.3 |

| Hallett 5 The Bluff WF | Wind | 52.5 |

| Hallett Stage 1 Hallett Hill | Wind | 94.5 |

| Hallett Stage 2 Hallett Hill | Wind | 71.4 |

| Hornsdale Windfarm Stage 1 | Wind | 102.4 |

| Hornsdale Windfarm Stage 2 | Wind | 102.4 |

| Hornsdale Windfarm Stage 3 | Wind | 112 |

| Lake Bonney 1 Wind Farm | Wind | 80.5 |

| Lake Bonney 2 Wind Farm | Wind | 159 |

| Lake Bonney 3 Wind Farm | Wind | 39 |

| Lincoln Gap Wind Farm – Stage 1 | Wind | 126 |

| Lincoln Gap Wind Farm – Stage 2 | Wind | 86.4 |

| Mt Millar Wind Farm | Wind | 72.28 |

| Snowtown | Wind | 98.7 |

| Snowtown S2 | Wind | 270 |

| Starfish Hill | Wind | 33 |

| Tailem Bend | Solar | 108 |

| Waterloo Wind Farm | Wind | 130.8 |

| Wattle Point | Wind | 90.75 |

| Willogoleche Wind Farm | Wind | 119.36 |

| Total | 2540.71 |

Reference: AEMO: NEM Generation Information July 2023

7.1.5. Transmission

The electricity transmission system transports power from power stations directly to a series of sub-stations and switchyards, which in turn supply the distribution system and directly connected transmission customers. The major transmission entity in South Australia, ElectraNet, owns and operates a network of approximately 6,454 circuit kilometres of transmission lines. The network operates at nominal voltages of primarily 275 kilo-Volts (kV) and 132 kV with a smaller number of 66 kV lines as shown in Table E3.

Table E 4: ElectraNet transmission network length

| Voltage (kV) | Overhead (km) | Underground (km) |

|---|---|---|

| 275 kV | 2,733 | 26 |

| 132 kV | 3,188 | 0 |

| 66 kV | 21 | 3 |

The South Australian electricity transmission network is connected to Victoria through the Heywood and Murraylink interconnectors.

ElectraNet operates 98 substations. Substations included in the transmission network are primarily of outdoor construction and air insulated. The network includes some gas insulated metal clad switchgear. ElectraNet does not own all of the assets or land at a number of substations; these sites are shared with other electricity entities, primarily SA Power Networks, the operator of the distribution network.

A system monitoring and switching centre for the transmission network is located in Adelaide and includes Supervisory Control and Data Acquisition (SCADA) facilities to monitor system conditions at substations and to control equipment in the network.

The transmission system is the backbone of electricity supply in South Australia and is being maintained at a high level of reliability and availability. A number of thermal generators and wind farms are connected to the transmission network at various locations throughout the State.

Murraylink Transmission Company

The Murraylink Transmission Company Pty Ltd runs an inter-regional transmission service comprising two high voltage direct current cables 176 km in length between Berri in South Australia and Red Cliffs in Victoria. At both ends of the cable is a DC-AC converter station to connect Murraylink to the existing transmission systems in South Australia (at 132 kV) and Victoria (at 220 kV).

Murraylink is a bi-directional facility with a steady state transfer capability of 220 MW at the receiving end. It provides South Australian consumers with access to generation from Victoria and New South Wales at times of local peak loads or generation shortfall. During off-peak periods, Murraylink is able to export excess South Australian generation to Victoria and New South Wales consumers.

7.1.6. Distribution

In South Australia, the entity primarily responsible for electricity distribution is SA Power Networks which serves approximately 909,615 customers. There are a number of smaller distribution entities covering remote areas. Some of these areas were managed by SA Power Networks under contract for the reporting period. The electricity distribution network in South Australia covers more than 178,000 km2. The network extends across difficult and remote terrain and operates in demanding conditions and stretches for over 90,167km, and includes 400 zone substations, 74,885 street transformers, more than 647,000 Stobie poles and 200,000 km of overhead conductors and underground cables. Some distribution substations are within sites shared with ElectraNet.

Table E5: Distribution network length at May 2023

| Operating Voltage | Overhead (km) | Underground (km) |

|---|---|---|

| Low Voltage (<1,000Volts) | 18,472 | 14,656 |

| 11 kV (includes 7.6kV) | 17,881 | 4,331 |

| 19 kV (SWER) | 29,108 | 66 |

| 33 kV | 3,992 | 140 |

| 66 kV | 1,454 | 54 |

| 132 kV ¹ | 11 | 0 |

| Total | 70,920 | 19,247 |

¹ Licence modified to allow for 132 kV distribution assets

SA Power Networks Key Performance Indicators (KPIs)

SA Power Networks KPIs cover service and technical Standards and include supply interruptions, power surges and low and high voltage complaints. SA Power Networks reports its performance against these KPIs, with reliability and outage indicators on a quarterly basis and all other indicators on an annual basis. The Technical Regulator receives and reviews these reports and follows up on any technical issues, where deemed appropriate, to ensure that corrective action has been taken or is planned. This reporting process ensures that the Technical Regulator is kept informed of major outages and provides assurance that the reliability of electricity supply is being maintained or improved. These KPIs are included in Table K2 in Volume IV of Appendix 1.

7.2. Smarter Homes Program

Following advice from AEMO, a number of technical standards and requirements for smaller generators such as rooftop solar have been introduced in South Australia and are in effect as of 28 September 2020. These requirements include:

- Voltage ride though Standards for generating systems connected to the electricity network via an inverter.

- Remote disconnection and reconnection requirements.

- Dynamic export limit requirements.

- Smart meter minimum technical standards.

- Tariffs to incentivise energy use in low demand periods.

Implementation and ongoing administration of these requirements by the OTR helps to ensure the power system in South Australia remains safe and reliable.

7.2.1. Voltage Ride Though Standards

From 28 September 2020 any generator connected via a low voltage inverter to the SA Power Networks electricity distribution network must comply with undervoltage ride- through performance standards designed to mitigate impacts on the South Australian power system during disturbances. The investors are approved, tested in accordance with AS/NZS4777.2 by the Clean Energy Council (CEC) and are listed on CEC website.

7.2.2. Remote Disconnect and Reconnect

In addition to Voltage ride though, newly installed prescribed grid connected generating systems are required to be capable of being remotely disconnected and reconnected by a Relevant Agent registered with the Technical Regulator. A Relevant Agent is a party who has been authorised and appointed by the owner or operator of the prescribed electricity generating plant by written authorisation to manage the requirement on their behalf. As of the 30 June 2023, the office of Technical Regulator has assisted and approved 29 Relevant agents with a total 491,561 KW plant capacity under their control.

7.2.3 Dynamic Export Limit Requirement

New technical standards now require that prescribed generating systems connecting to the South Australian distribution network after 1 July 2023 are capable of being export limited and for export limits to be updated remotely. Together these concepts are referred to as Dynamic Exports and are being implemented via the SA Power Networks flexible exports program.

7.2.4. Smart Meter Minimum Technical Standards

As of 28 September 2020, the standard requires a smart meter to be capable of separately measuring and controlling an electricity generating plant and controllable load from essential load. Smart meters must be installed in accordance with the guidelines issued by the Technical Regulator and the meter installation is required to comply with the Technical Regulator Guideline - Smart Meter Minimum Technical Standard.

7.2.5. Tariffs to incentivise Energy

This requirement which is in effect as of 28 September 2020 applies to retailers' standing offers for customers with interval meters. This ensures retailers make offers that reward customers for using electricity in low demand periods. These will typically include a ‘time of use’ tariff, which incentivises energy use during the day while disincentivising energy use during the evening and overnight.

7.3. Safety Clearances to Powerlines

The Technical Regulator is responsible for the administration of the provisions of the Electricity Act 1996 relating to the safe clearance of buildings and structures, workers and equipment, and vegetation from powerlines.

Where there is a dispute relating to either vegetation or building clearances, the Technical Regulator strives to facilitate a sensible, safe and agreeable resolution that complies with the requirements of the legislation.

7.3.1. Vegetation Clearance

The Technical Regulator administers the Electricity (Principles of Vegetation Clearance) Regulations 2021 which include:

- The required clearance distances and the normal clearance cycle of vegetation.

- The list of species of vegetation which may be planted or nurtured near powerlines.

- Providing the occupiers of land an opportunity to lodge an objection in relation to vegetation clearance issues.

- Bushfire risk boundaries which dictate clearance distances between overhead powerlines and trees or other vegetation.

Risks associated with Vegetation near Powerlines

The risks directly associated with vegetation contacting powerlines include electric shocks, fire, damage to infrastructure and interruptions of supply. To protect people and property from these risks, clearance zones and buffer zones (which limit the amount of pruning of vegetation) and planting restrictions have been established under the Electricity (Principles of Vegetation Clearance) Regulations 2021.

In South Australia, a special case for concern is the risk of bushfires being started by overhead powerlines. This risk is principally managed through vegetation clearance, keeping flammable material well away from powerlines.

Vegetation Clearance Objections

Electrical entities conduct a periodic vegetation inspection at intervals of no longer than three years. In bushfire risk areas, annual inspections are conducted prior to the bushfire season. When an electricity entity identifies vegetation on private property as requiring trimming or removal, the entity is required to provide the owner or occupier with a 30-day notice of intention to enter the property to cut vegetation. The owner or occupier then has 21 days after receiving the notice to lodge a written notice of objection with the Technical Regulator. The Technical Regulator holds regular meetings with SA Power Networks and Active Tree Services’ management throughout the year, to discuss any disputes or other matters regarding vegetation near powerlines, which had come to the attention of the Technical Regulator.

Vegetation Clearance Agreements

The Electricity Act 1996 makes provision for electricity transmission and distribution entities and Councils to enter into agreed vegetation clearance schemes under which vegetation clearance responsibilities may be conferred on a Council. A Council also may agree to pay for the cost of more frequent clearance in order to reduce the scale of a three-yearly pruning by the entity. There are currently no such agreements in place between any Council and SA Power Networks.

7.3.2. Building and Working Clearances

The Electricity (General) Regulations 2012 define the minimum clearances between buildings or structures and powerlines. Section 86 of the Electricity Act 1996 also gives the Technical Regulator power to grant an approval (subject to limitations as specified in the Electricity (General) Regulations 2012) for a building or structure to be erected within the prescribed clearance distances.

Risks associated with Buildings near Powerlines

Minimum building clearances are defined in the legislation to prevent electric shocks, damage to infrastructure or property, and to ensure the reliability of supply.

The Technical Regulator actively promotes awareness of these legislated distances within the construction industry by providing verbal and written advice and presentations, undertaking site assessments, and distributing information via brochures and the internet.

The Electricity Act 1996 makes provisions for an electricity entity to rectify identified breaches of minimum safety clearances and recover the costs by means of a court order.

Compliance with Building Clearances

The Office of the Technical Regulator worked with network operators, builders and other stakeholders to resolve numerous under construction and completed buildings found to be within the minimum building clearances defined in regulation.

Often these are resolved by costly modification of the electricity infrastructure – a large expense added to the cost of a building, highlighting the importance of proper planning when designing structures in proximity to powerlines and other electricity infrastructure.

Section 8: Electrical Installation

8.1. Regulatory Framework

The safety of electrical installations is mandated by the Electricity Act 1996 and the Electricity (General) Regulations 2012. This legislation defines the powers, rights and responsibilities of the various parties in relation to the safety of electrical installations. The Electricity (General) Regulations 2012 mandate compliance with AS/NZS 3000 – Wiring Rules as well as the technical installation rules of the network operator.

Key issues covered by the Electricity Act 1996 and the Electricity (General) Regulations 2012 include placing the responsibility for the safety of an electrical installation with the owner or operator of that installation, and the reliance on a Certificate of Compliance as a means of demonstrating that this responsibility has been met. Likewise, the person connecting the installation to the network (typically the network operator) can rely on the Certificate of Compliance to demonstrate they have met their obligation regarding the safety and compliance of the installation.

Occasionally, installations and appliances are deliberately misused by unlicensed persons involved in illegal activities, for example in the manufacture of illegal drugs.

8.2. Compliance Audits

Audits may be random or targeted. Targets for random audits are obtained from data such as lists of new connections and alterations such as solar installations supplied by network operators. Targeted audits are performed following complaints, concerns from past performance or intelligence gathered from the industry.

The Technical Regulator inspects electrical installations against requirements specified in AS/NZS 3002 for outdoor events due to their temporary nature, and the high levels of potential risk involved.

Figure E 1: Non-compliant electrical installation at a major event

The figure above shows the circled cable is too low, has no secondary support and is not flagged. Other specialist areas that are audited include recreational vehicles, caravan parks, boats and marinas, hazardous areas and patient areas.

8.3. Electrical Helpline

Electrical workers and contractors are encouraged to call the Technical Regulator for assistance with technical compliance matters. This proactive strategy helps the industry achieve compliance in a timely manner. The helpline is available 8am-4.30pm Monday to Friday.

8.4. Enforcement

The Technical Regulator has a range of enforcement options to deal with non-compliant electrical installation work and other breaches of the Electricity Act 1996.

8.4.1. Directives to make installation safe

An authorised officer can give a direction to make an electrical installation safe. This direction can be given to the owner or operator of the installation or to the person who performed the work. In some cases, this may also include disconnection of the installation until it is repaired and made safe to the satisfaction of the authorised officer.

8.4.2. Formal warnings

A formal warning can be given to the person responsible for breaching the Electricity Act 1996. If this is done verbally it is also confirmed in writing. Formal warnings provide a basis for additional enforcement activity should there be an escalation of the offence, in addition to establishing patterns of repeated non-compliance.

8.4.3. Expiation Notices

Expiation notices are issued for more serious breaches of the Electricity Act 1996. They are an administrative penalty that is intended to minimise the impacts on the courts and legal system caused by relatively minor offences. The issue of an expiation notice does not register a conviction against the alleged offender, and paying the expiation fee is not considered to be an admission of guilt. Expiation notices can be challenged in court by the alleged offender, who could then face the potential of a significantly higher penalty if found guilty.

8.4.4. Prosecution

The Technical Regulator may prosecute a person where the non-compliance is so serious as to constitute gross negligence or where the offender has a history of significant non-compliance.

The court will then decide the actual penalty up to the maximum stated in the Electricity Act 1996 or Electricity (General) Regulations 2012 should the person be found to have committed the offence or breach.

8.4.5. Suspension/cancellation of licenses

In cases of serious or consistent non-compliance, the Technical Regulator may refer a case to the Commissioner for Consumer Affairs (who is responsible for occupational licensing under the Plumbers, Gas Fitters and Electricians Act 1995) for action. This may result in the suspension or cancellation of a contractor’s licence or worker’s registration, or the imposition of conditions on that licence/registration.

Instances of electrical work performed by non-licensed/registered persons are also forwarded to the Commissioner.

8.5. Reporting of Electric Shocks

All incidents that result in electric shocks or burns must be reported to the Technical Regulator. In the case of death, this must be done immediately. If a person requires medical treatment it must be reported within one working day. All other instances must be reported within 10 working days.

This allows an appropriate time for the incident to be investigated. The Technical Regulator investigates electrical fatalities, usually in conjunction with SA Police. Other investigations are normally performed by registered electrical workers. Incident reports help prevent recurrences of the event and may result in enforcement action being taken. Statistical data from shock and incident reports also assist with resource allocation and scope for potential changes to electrical Standards.

Section 9: Electrical Products

The Energy Products (Safety and Efficiency) Act 2000 is administered by the Technical Regulator and requires that proclaimed classes of electrical products must comply with specified safety and performance Standards and be labelled to show compliance before sale (see Appendix 4).

Other Australasian jurisdictions have similar legislation. The Technical Regulator works with other Australasian Regulators and Standards Committees to ensure a nationally consistent electrical product safety regulatory regime.

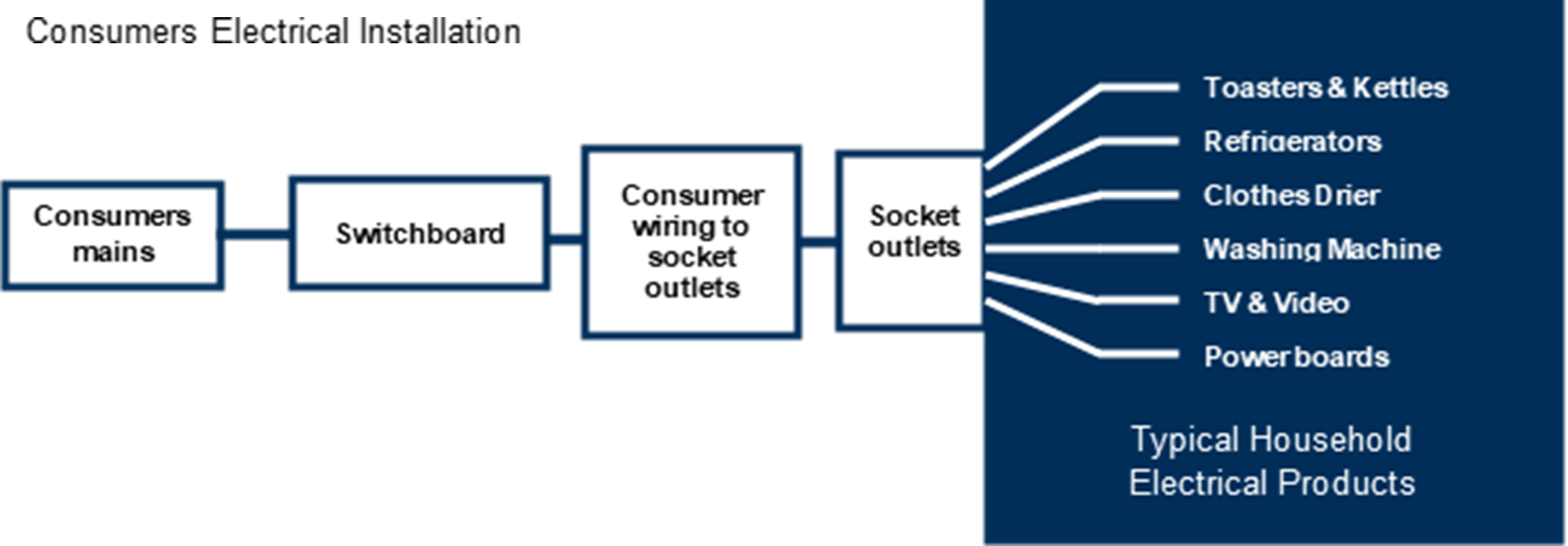

Figure E 2: Boundary of installations from products

An electrical product is any device that needs to be connected to the household electricity supply. This includes such items as white goods, power tools, portable household products, power boards, air conditioners and hot water services. It is estimated that the typical household has up to 50 electrical products.

The Technical Regulator investigates reports of breaches of the Energy Products (Safety and Efficiency) Act 2000. This can result in the issue of stop sale notices, public warning statements, product recalls, expiation notices or prosecution.

9.1. Role of the Technical Regulator

The Technical Regulator, in accordance with the Energy Products (Safety and Efficiency) Act 2000, grants electrical products safety labelling certificates and electrical product suitability certificates to applicants. The certificates are required to label electrical products to indicate their compliance with applicable Standards or certify their suitability to connect to an electricity transmission or distribution network before sale.

The Technical Regulator also follows up these products after sale, through field audits and product investigations, based on reported failures.

The Technical Regulator is represented on national regulatory and Standards committees, the aim of which is to ensure that regulators act in a coordinated manner throughout Australia and that the safety Standards impose a common, acceptable level of safety. These committees are listed in Section 10.2.

The Technical Regulator also provides technical advice to manufacturers and importers, the electrical industry, government agencies and emergency services.

9.2. Product Safety

9.2.1. Product Approval

There are 64 classes of products proclaimed under the Energy Products (Safety and Efficiency) Act 2000, which must comply with specified safety and performance Standards. This list has evolved over time, and typically includes household products that, in the past, have been involved in numerous fires and/or electric shock incidents and therefore represent a ‘high risk’ category. These products, which are covered by similar legislation in all Australian States, require pre-market approval and must carry an approval label to indicate their compliance with safety and performance Standards before they can be sold. Appendix 4 lists these proclaimed products.

9.2.2. Product Approval Safety Process

In South Australia, the current approvals process requires manufacturers or importers to submit samples of proclaimed products for testing at accredited laboratories to ensure their compliance with the applicable Australian/New Zealand safety and technical Standards. These Standards set down the basic requirements that the products must meet to be considered electrically safe. Typically, these requirements include levels of protection to guard against such things as unsafe construction, access to live parts, overheating from normal or abnormal operation and fire propagation.

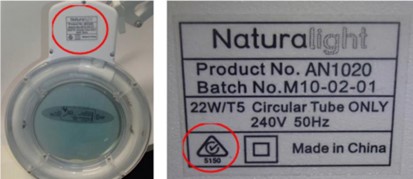

Testing must be carried out in accordance with the relevant Standards by appropriate test laboratory facilities in Australia or overseas. In Australia, this means a testing facility that has National Association of Testing Authorities (NATA) accreditation. Evidence of compliance can then be submitted to the Technical Regulator or a private certifier, who will verify compliance and then issue a certificate. This certificate is generally valid for five years. When offered for sale, the product must carry the allocated approval marking. If issued by a State regulator or private certifier, the marking contains a letter identifying the State or certifier who approved it, followed by its allocated number (e.g. Victoria – ESVxxxxx, South Australia – S/xxx or OTRxxxxxx), private certifier marking (alpha numeral), or if AS/NZS 4417 (marking of electrical products to indicate compliance with regulations) is complied with, the Regulatory Compliance Mark (RCM) symbol as defined in that Standard as shown below.

Figure E 3: Regulatory Compliance Mark

Figure E 4: Example of approval labelling for an OTR (S marking) approved product – wall switch

Figure E 5: Example of the RCM approval labelling symbol for an approved product – desk lamp

Each State in Australia recognises approvals issued by the other State authorities and product certifiers. There are also alternative private certifying bodies which have been recognised interstate, resulting in approval labelling other than that issued by a State

Regulator, with a consequent reduction in the number of products being approved by State authorities. The nature of the retail products industry is such that competitors quickly identify any unapproved items for sale and report them to the Technical Regulator, who is then able to take immediate action for breaches of the Energy Products (Safety and Efficiency) Act 2000.

9.2.3. Risks Due to Faulty or Misused Products

The risks associated with electrical products that have failed because of their design, or manufacture, or misuse by the consumer include:

- Personal injury (shocks).

- Electrocution (fatalities).

- Property damage (fires).

Manufacturers, importers and retailers also assume liability through the sale of electrical products for:

- Costs of recalls, replacement or repair of products.

- Costs of compensation claims.

- Loss of, or damage to, the organisation’s reputation.

Hazardous Products

Typical hazards found in faulty electrical products include:

- A breakdown of insulation due to overheating or mechanical damage, which may expose the consumer to the risk of electrical shock.

- Overheating of the product, which may result in fire or ignition of its surroundings, exposing consumers to the risk of injury or property damage.

- Mechanical failure, which may cause personal injury to the user.

Figure E 7: Example of an electrical product failure

Figure E7 illustrates the consequences of a faulty electrical connection in a washing machine that overheated and caught fire.

Figure E 8: Example of an electrical product failure

Figure E8 illustrates the consequences of a bathroom heater glass diffuser shattering whilst in use, resulting in the user receiving burns and cuts.

Products may also fail because of misuse by the consumer. Typical examples of this are:

- Incorrect securing of electric blankets resulting in folds that lead to overheating and fire.

- Unsafe placement of radiators and fan heaters adjacent to furniture and materials, resulting in fires.

- Continued use of electrical products with damaged bodies and cords, resulting in electrical shocks.

- Not having products checked after being subjected to an impact or falling from a height.

Figure E9 shows an example of brand new decorative LED rope lights that started to emit smoke and deform within minutes of use, as a result of the user not observing the warning instructions to remove the packaging.

Figure E 9: Incident due to user not observing the warning instructions

In many cases, products are either incorrectly installed or operated by consumers who do not follow the manufacturer’s recommendations and instructions. The Technical Regulator alerts consumers and electricians to such risks through public warnings, the continuous development of information brochures, Regulation Roundup and education programs.

9.2.4. Product Failures and Corrective Actions

The Technical Regulator monitors the failures of electrical products. If necessary, action can be taken under the Energy Products (Safety and Efficiency) Act 2000 to remove any hazardous products from the marketplace. Depending on the severity of the failure, there are a number of options available to the Technical Regulator when assessing what action should be taken for specific situations including:

- Issuing an Incident Report – when the failure of a product has not directly resulted in a safety hazard. The report is circulated to all regulatory authorities throughout Australia and New Zealand for information and monitoring.

- Issuing a Hazard Alert – when the failure of a product has resulted in an immediate safety problem such as a reported electric shock. The notice is immediately circulated to all regulatory authorities including both State and Australian Government consumer affairs authorities for information and followed up by action with the trader as considered necessary.

- Issuing a Stop Sale – generally issued in conjunction with a Hazard Alert. The notice is circulated to all regulatory authorities including both State and Australian Government consumer affairs authorities for information and is followed up by action with the trader.

- Issuing a Recall – when a product already on the market has been identified as a safety hazard. This may warrant the issuance of a recall notice and result in a national public product recall conducted in accordance with Australian Competition and Consumer Commission (ACCC) guidelines.

9.2.5. Stop Sales

The Technical Regulator can issue Stop Sale notices to traders in South Australia as the situation warrants. An example of a situation requiring the seller to “Stop Sale” is when the product is proclaimed under the Energy Products (Safety and Efficiency) Act 2000, but is not marked with any approval labelling indicating that it is formally approved for electrical safety.

9.2.6. Mutual Recognition

Under a Mutual Recognition Agreement (MRA) between two or more jurisdictions, one jurisdiction is able to recognise a product approval issued by another.

Apart from the ‘corresponding laws’ recognised under the Energy Products (Safety and Efficiency) Act 2000, several mutual recognition schemes affect the Technical Regulator’s operations and those of other State Regulators.

Australian Mutual Recognition

The Mutual Recognition (South Australia) Act 1993 and the Mutual Recognition Act 1992 (Commonwealth) provide that, in principle, a product made in or imported into a State that can be lawfully sold in that State, may be lawfully sold in any other State. A label is required showing the place of manufacture or importation to enable a defence of mutual recognition to be established.

Trans-Tasman Mutual Recognition Arrangement (TTMRA)

The Trans-Tasman Mutual Recognition (South Australia) Act 1999 and the Trans- Tasman Mutual Recognition Act 1997 (Commonwealth) provide that, in principle, products made in or imported into New Zealand that may be lawfully sold in New Zealand, may also be lawfully sold in Australia. A label on the product is required showing the place of manufacture or importation to enable a defence of mutual recognition to be established.

The TTMRA has resulted in some products either manufactured in or imported into New Zealand being offered for sale in Australia without any identifiable approval marking as New Zealand law does not require such labelling.

9.3. Product Energy Efficiency

Energy labelling and Minimum Energy Performance Standards (MEPS) registrations are now regulated by the Australian Government’s Greenhouse and Energy Minimum Standards Act 2012 (GEMS legislation). The energy efficiency requirements of the Energy Products (Safety and Efficiency) Act 2000 are still applicable but in general terms have become redundant.

9.4. Industry Communication

There are only a few South Australian businesses (including manufacturers, importers and retailers) that submit electrical products to the Technical Regulator for approval. The Technical Regulator distributes newsletters and circulars to these businesses to keep them informed of changes to the Energy Products (Safety & Efficiency) Act 2000 and Australian Standards as necessary.

Section 10: Electricity Regulatory Coordination

10.1. Electrical Regulatory Authorities Council (ERAC)

National uniformity and consistency are extremely important to electricity utility operators, manufacturers, electrical workers, contractors and consumers. ERAC has representatives from all Australian States and Territories and New Zealand. It formally meets twice per year to address regulatory matters related to key technical and worker licensing issues facing the electrical industry and to develop national strategies to address these issues consistently.

Meetings are divided into five sessions, each with their own chairperson, covering general matters, electrical installations and inspection, electrical equipment safety, electrical licensing and electricity supply (network infrastructure).

ERAC works closely with Standards Australia to maintain and develop national Standards which in turn become State-based requirements when they are called up by legislation. The Technical Regulator, as a member of ERAC, actively participates in Standards development issues arising from ERAC meetings. The Technical Regulator also participates in a number of ERAC working groups to ensure that national developments take account of South Australian issues.

Uniform Standards are beneficial in that they provide for the movement of workers between regions and enable the development of Standards based on the experience of a wider group. The national Standards development process also supports the ongoing review and improvement of safety Standards in a transparent manner. ERAC has been active in setting the agenda for the progressive review and implementation of network safety Standards. This has included a Standard dedicated to safety issues associated with smart meters.

ERAC has been particularly keen to support the timely development of Standards which deal with matters that have a direct impact on the interface between the network industry and the public, such as powerline clearances.

Following its review of the regime for regulating electrical equipment safety in Australia, ERAC has recommended an updated system aimed at eliminating shock, injury and property damage resulting from the sale, supply and use of unsafe electrical equipment. ERAC has proposed that the new system should be underpinned by nationally consistent performance-based legislation in each jurisdiction and comprehensive scheme rules. It contains a mixture of pre-market registration based on third party safety assessment and post-market enforcement.

The system will be designed to take into account the changing character of the electrical appliance supply industry in Australia. The recommendations formed the basis of the Regulatory Impact Statement (RIS), released for public comment by ERAC. Following consideration of public submissions on the RIS and further industry consultation, a final RIS was endorsed by ERAC members. In order for a national scheme to be agreed and implemented, ERAC is in the process of developing an intergovernmental agreement (IGA) between all states and territories to gain Ministerial agreement to progress the scheme.

The then Ministerial Council on Energy (MCE) established the Energy Technical and Safety Leaders Group (Leaders Group). The Leaders Group was tasked with the development of a plan to achieve further harmonisation of State and Territory safety regulation for the electricity and gas supply industry.

The plan presented by the Leaders Group contains recommendations for achieving a harmonised national framework within which State and Territory energy supply industry safety and technical regulations could operate. The plan proposes an IGA as the central mechanism by which jurisdictions would commit to a series of overarching principles and objectives supporting harmonisation. The then MCE gave in-principle agreement to the recommendations contained in the plan as they apply to Energy Ministers’ portfolio responsibilities. The then MCE Ministers also agreed to work with related portfolio Ministers within their jurisdiction to progress the proposed IGA. The objective of the IGA is to create a nationally harmonised energy supply industry safety framework, to ensure enhanced public and industry safety, enhance worker mobility and contribute to the efficient delivery of energy network services. In particular, the IGA will formalise governments’ commitment to make necessary legislative or other changes to support the nationally harmonised safety framework for the energy supply industry. The IGA does not commit to the development of a model or applied legislation.

As part of the harmonised safety framework, the IGA commits participating jurisdictions to an ongoing work program in Standards development (such as the Australian Standard for Energy Network Safety Systems), operating safety rules and skills and training. This work would be supported by the Energy Supply Industry Safety Committee (ESISC), a non-statutory advisory body that provides advice, knowledge and expertise on the development and implementation of the nationally harmonised safety framework. In 2012, the Australian Government, States and Territories endorsed the IGA on Energy Supply Industry Safety by the signature of First Ministers. Under the IGA, the Australian Government and the State and Territory governments agree to put in place a nationally harmonised safety framework for the energy supply industry. The Terms of Reference (TOR) for the ESISC came into effect with the signing of the IGA. The TOR tasked ESISC to develop and implement a nationally harmonised safety framework for the energy supply industry.

The TOR requires that ESISC submit to the Energy Senior Officials Meeting for approval of the ESISC implementation plan for five years. This plan requires a progress update every 12 months on:

- Energy Network Safety Systems.

- Consistency with National Work Health And Safety.

- Consistency with National Occupational Licensing System Initiatives.

- Legislative And Regulatory Issues.

- Expanded National Refresher Training Recognition Protocol For The Electricity Supply Industry.

- Generation Harmonisation.

- Harmonised Operating Safety Rules.

A key outcome of this work was the development and publication on 18 April 2013 of the Australian Standard AS 5577:2013 Electricity Networks Safety Management Systems.

The Standard provides a national framework for the harmonisation of energy network safety systems.

10.2. Committee Representation

The Technical Regulator provides expert technical input for the revision of key Australian Standards through representation on the following Standards committees:

| EL-001 | Wiring Rules |

| EL-001-09 | Wiring Rules Drafting Subcommittee |

| EL-001-17 | Construction and Demolition Sites Installations |

| EL-001-21 | Testing and Inspection of Electrical Installations |

| EL-001-24 | Generating Sets |

| EL-002 | Safety of Household and Similar Electrical Appliances and Small Power Transformers and Power Supplies |

| EL-004 | Electrical Accessories |

| EL-011 | Electricity Metering Equipment |

| EL-042 | Renewable Energy Power Supply Systems & Equipment |

| EL-042-03 | Grid Connected Systems and Equipment |

| EL-042-05 | Safety of Battery Systems for use in Inverter Energy Systems |

| EL-044 | Safe Working on Low-Voltage Electrical Installations |

| EL-052 | Electrical Energy Networks, Construction and Operation |

| ET-007 | Coordinating Committee on Power and Telecommunications (CCPT) |

| QR-012 | Conformance Marking to Regulatory Requirements |

Volume II – Gas Industry

Preface

This volume covers the Technical Regulator’s operations under the Gas Act 1997.

Gas Act 1997

Section 3 of the Gas Act 1997 states that:

“The objects of this Act are—

(a) to promote efficiency and competition in the gas supply industry; and

(b) to promote the establishment and maintenance of a safe and efficient system of gas distribution and supply; and

(c) to establish and enforce proper standards of safety, reliability and quality in the gas supply industry; and

(d) to establish and enforce proper safety and technical standards for gas installations and appliances; and

(e) to protect the interests of consumers of gas.”

The Technical Regulator is established by section 7 of the Gas Act 1997.

Section 8 of the Gas Act 1997 states that:

“The Technical Regulator has the following functions:

(a) the monitoring and regulation of safety and technical standards in the gas supply industry; and