Common salt or sodium chloride (NaCl) is one if the most widely used substances on Earth, with ~14 000 direct and indirect uses reported. It is composed of 39.3% sodium and 60.7% chlorine by weight, and has been given the mineralogical name halite. World consumption is ~200 Mt/year.

Common salt or sodium chloride (NaCl) is one if the most widely used substances on Earth, with ~14 000 direct and indirect uses reported. It is composed of 39.3% sodium and 60.7% chlorine by weight, and has been given the mineralogical name halite. World consumption is ~200 Mt/year.

The most familiar use of salt is as a food preservative and additive. It is an excellent carrier of iodine in the form of potassium iodide, and its widespread use in food makes it an ideal medium for the prevention of iodine deficiency disorders to which about one billion people are at risk, mainly in developing countries. Other common uses are in the leather tanning industry, commercial dye manufacturing, and in the pulp and paper industry. It is also used in domestic and commercial ion exchange water softeners where sodium ions are released from a resin bed in exchange for the capture of calcium and magnesium ions which cause ‘hardness’ in water. In cold northern hemisphere countries, large amounts of salt are used as a de-icing agent on roads.

Salt is an important feedstock to the chloralkali branch of the chemical industry, being the cheapest and most common source of soda ash (Na2O) via the Solvay process (see Limestone commodity review). Caustic soda (NaOH) and chlorine (Cl2) are produced by electrolysis of salt brine feedstock. Chlorine is used to make a wide variety of chemicals including hydrochloric acid, chlorinated hydrocarbons, and polyvinyl chloride (PVC).

Large sedimentary deposits of salt occur in many countries throughout the world, but the largest resource is in the world’s oceans which contain 530 million cubic kilometres of water averaging 78 Mt of salt per cubic kilometre.

Most of the world’s salt supplies are obtained by solar evaporation of seawater, which contains on average 3.6% dissolved salts, of which sodium chloride comprises 77%. Seawater is exposed to the action of sun and wind in a chain of concentrating ponds, to the point where it becomes saturated with common salt. The less soluble salts, iron oxide and calcite, followed by gypsum, are precipitated out at this stage. The water is then pumped into crystallising ponds where common salt precipitates. The process is stopped before all the salt comes down in order to avoid contamination with magnesium and potassium salts. The final liquors, known as bitterns, are drained away from the salt which is then harvested.

The Australian annual production of ~8 Mt is dominated by Western Australia. All South Australian salt is produced by solar evaporation of seawater or saline lake water. Seawater is unique in the world of commodities in that is is the only renewable, with practically speaking, and endless supply of seawater. The 2013 harvest of salt in South Australia was 870,000 tonne.

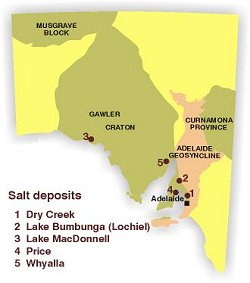

Salt production in South Australia

South Australia has a long history of salt production. In fact for many decades it was Australia’s largest producer, with much of that production coming from operations on the lower Yorke Peninsula.

In the late 1960s the Geological Survey completed a scoping study at the Weavers Lagoon prospect. The operation involved recovery of salt from highly saline groundwater in host Kulpara Limestone, pumped from the aquifer to the surface at Weavers Lagoon. The potential reservoir was very large, estimated volume 1136 milion m3 or 1265 Mtonne salt.

Dry Creek

ICI began salt production at Dry Creek in 1940 and, after almost 50 years of production, sold the operation to Penrice Soda Products in 1989. The saltfields cover ~4000 ha near the coast north of Adelaide. Salt water is pumped from the sea at two pumping stations, 20 and 30 km north along the coast from the final crystallising area. Harvested salt is redissolved and pumped as brine to Osborne for manufacture of soda ash by the Solvay process. Production in 1999 was 391 000 t.

Price

Salt has been produced by solar evaporation of seawater at Price since 1919. The operation, run by Cheetham Salt Ltd, comprises 1064 ha of evaporators and crystallisers and a processing plant which produces bagged and packaged salt for industrial and household use. Production in 1999 was 88 000 t. Bulk salt is sent to Cheetham’s Geelong refinery (Victoria), or is shipped to overseas markets in New Zealand and South East Asia from BHP’s loading facilities at Ardrossan.

|  |

Northerly aerial view of pink-coloured crystallisers of Dry Creek Saltfields | Harvesting salt at Price |

Lochiel

Salt has been produced at Lochiel since 1912, where it is dissolved from saline mud by winter rains filling a 1500 ha inland lake. The resulting brine is pumped into three 25 ha crystallisers, from which Cheetham Salt Ltd produced 4000 t in 1999.Lochiel

Lake MacDonnell

Salt is produced by solar evaporation of brine which seeps into a shallow lake through porous coastal dunes, or which is pumped from the nearby gypsum operations. The 1999 production from 71 ha of crystallising pans was 35 000 t. Salt is either processed and bagged on site at Cheetham’s plant, or railed in bulk 64 km to Thevenard for shipment to markets in South East Asia and New Zealand, or to the company’s Geelong refinery.

Whyalla

BHP began salt production at Whyalla in 1951 by solar evaporation of seawater. In 1979, Pacific Salt Pty Ltd built a processing plant on site and in 1988 took over production; 47 000 t were produced in 1999 from 240 ha of brine ponds and 20 ha of crystallisers.

Additional Reading

Valentine, J.T., 1989. Industrial and non metallic minerals - operations in South Australia. South Australia. Department of Mines and Energy. Report Book, 89/74:104-122.