On this page

Pipelines

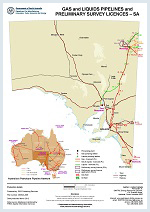

Over 5000 km of pipelines have been laid from the Cooper Basin to gas markets in eastern and southern state capitals and to the liquids load out facility at Port Bonython. Over one million residential, commercial and industrial customers in South Australia, New South Wales, Australian Capital Territory and Victoria are directly supplied from South Australia. Key pipelines in the region are Santos Ltd’s Moomba to Port Bonython liquids line and Epic Energy South Australia’s (EESA’s Moomba to Adelaide gas pipeline, both operated by EESA; the Port Campbell to Adelaide gas pipeline, owned and operated by South East Australia Gas Pty Ltd (SEA Gas); and the Moomba to Sydney sales gas pipeline and the QSN Link gas pipeline, both owned and operated by the APA Group, the ethane pipeline, operated by the APA Group on behalf of Gorodok Pty Ltd. Download the map of Gas and liquids Pipeline & Preliminary Survey Licences.

The Moomba to Adelaide gas pipeline is 781 km long, the maximum allowable operating pressure (MAOP) for the mainline is 7320 kPa and its fully compressed capacity (with all seven compressor stations online) is approximately 110 PJ (104 bcf) per year. In its current configuration (four compressor stations online) the annual capacity of the pipeline is around 91 PJ. This can be restored to maximum capacity if market conditions dictate. Lateral extensions to the main line total a further 607 km and service various markets in regional South Australia. The Riverland pipeline system, owned by Envestra (SA) Ltd and operated by APT O&M Services Pty Ltd extends from the Moomba to Adelaide pipeline and services Murray Bridge, Berri and Mildura.

Cooper Basin sales gas is sold to the New South Wales markets via the Moomba to Sydney Pipeline, a 1760 km network of transmission gas pipelines (current MAOP 5500 kPa). The current capacity of the Moomba to Sydney Pipeline is 152 PJ (139.3 bcf) per year.

Since January 2009, the Queensland to South Australia/New South Wales (QSN) Link Pipeline between Ballera (Qld) and Moomba (SA) has transported sales gas sourced from coal seam methane reserves in south-eastern Queensland directly into the Moomba to Adelaide Pipeline. The QSN Link Pipeline also connects directly into the Moomba to Sydney Pipeline. With a design capacity of 400 TJ/day when fully compressed, the QSN Link has increased the security of gas supply to the Adelaide market. In 2013, APA commenced the construction of a c compressor station at Moomba to allow for the reversal of flow in the QSN Link, sporting Cooper Basin Gas to Queensland and the impending East coast LNG export market

It is expected that the compressor station will be commissioned in late 2014.

Ethane is provided as feedstock for a petrochemical plant in Sydney via a dedicated 1375 km pipeline (MAOP 15 300 kPa) owned by Gorodok Pty Ltd and operated by the APA Group.

According to the Australian Energy Market Operator 2013 South Australian Generation Information, just over 57% of South Australia’s electricity generation capacity is dependent on natural gas for fuel.

The 659 km Moomba to Port Bonython Pipeline transports hydrocarbon liquids, sourced from both South Australia and Queensland, for processing at Port Bonython and export to national and international markets. The MAOP of the Moomba to Port Bonython Pipeline is 10340 kPa.

SEA Gas’ Port Campbell to Adelaide Pipeline was built in 2002–03 and commercial gas supply commenced on 1 January 2004. The 690 km pipeline transports offshore Otway Basin gas from the Iona gas facility in Victoria to Adelaide (Fig. 1). Two short lateral pipelines extending from the main line to industrial customers within South Australian have been constructed since this time. The Port Campbell to Adelaide Pipeline has a current capacity of around 110 PJ/y, which could be increased with additional compression.

The South East Pipeline System, owned and operated by EESA, has been supplying gas from the Otway Basin to local domestic and industrial users since early 1991. This system consists of a 46 km long pipeline from the Katnook gas processing plant to the APCEL paper mill operated by Kimberley Clark at Snuggery, 7 km SE of Millicent. A second line runs from this line to Mount Gambier, and a third line runs from Katnook due east to the Union Dairy Milk Powder Plant. A fourth line was constructed in the second half of 2000, connecting Kalangadoo to Nangwarry timber mill. This pipeline system has a maximum operating pressure of 10 000 kPa, and no compression is installed.

Origin Energy Retail Ltd constructed and commissioned the SESA Pipeline in 2005. This 45 km pipeline connects the Port Campbell to Adelaide Pipeline in Victoria to Epic Energy’s South East Pipeline System and the Ladbroke Grove Power Station, both in South Australia. The SESA Pipeline has a design capacity of 40 TJ/d and is now owned and operated by the APA Group.

Contact information and details of pipeline operators and tenements can be found within the quarterly Licence Information brochure (P1).

Pipeline preliminary survey licences

Under the Petroleum and Geothermal Energy Act 2000 a preliminary survey licence (PSL) can be granted to a potential pipeline or flowline constructor to authorise access to land to undertake survey activities, for the purpose of marking out the proposed pipeline route. There are currently two PSL Applications in South Australia for an export oil pipeline out of the Cooper Basin and a flowline proposals to transport gas from well sites to facilities within the Cooper Basin.

To streamline the application process, a statewide Statement of environmental objectives for pipeline preliminary survey activities is available for use by proponents wanting to undertake pipeline preliminary survey activities in South Australia. This can be downloaded from the Environmental Register.

Production facilities

Cooper and Eromanga basins

Gas emerges at the wellhead at pressures of up to 25 000 kPa and temperatures of up to 120 ºC. Gas from individual wells passes via field gathering systems (flowlines) to field satellite stations which separate gas, free water and condensate. Water disposal can be a major issue for oil production. Water is disposed of using evaporation ponds at the satellites. The essentially water-free gas and condensate pass to the central Moomba treatment plant through trunklines. Crude oil is transported by either pipeline or truck to the Moomba plant. Currently, Santos operates 12 oil and 12 gas satellites in the Cooper and Eromanga basins. Oil satellites are also operated by Senex Energy Ltd, Beach Energy Ltd and Acer Energy Ltd

The production facilities are connected by a series of unsealed roads, comprising 460 km of main road and 1860 km of access roads, which are maintained by the current operator. In addition, there are some public roads in the area which are maintained by the South Australian Department of Planning, Transport and Infrastructure.

At the Moomba plant any free condensate and water are initially removed from the raw gas at the slug catchers. The gas stream then proceeds to the carbon dioxide Benfield plant to ensure that no greater than 3% by volume of carbon dioxide remains in the sales gas stream. The gas is dehydrated at the molecular sieves before it proceeds to the liquid recovery plant where 100% of the remaining condensate, 98% of the LPG (C3 and C4) and 75% of the ethane are removed, leaving sales gas for Adelaide and Sydney with a heating value not less than 37.5 MJ/m3. ~8% of the sales gas is used as plant fuel at Moomba. The plant has been designed to process 25.4 x 106 m3 (902 mmcf) of raw gas, and 6000 kL (42 000 bbl) of condensate and crude oil per day. Since the commissioning of the SEA Gas Pipeline (which provides an alternative gas supply to South Australia), the plant is not operating at its maximum capacity. Processed sales gas is stored underground in the lower Daralingie Formation in times of low demand. This gas is removed from storage and produced during times of peak demand.

Condensate, LPG, crude and some ethane are transported as a ‘cocktail’ via a pipeline to Port Bonython where they are separated and marketed. The feedstock delivered to Port Bonython is sampled, filtered and metered, then pumped through fractionating towers to separate ethane (used as fuel gas for the plant), propane, butane, light, intermediate and heavy naphtha, and reduced crude. Once cooled to ambient temperatures, naphtha and reduced crude fractions are mixed together in precise ratios. The resulting two products, naphtha and crude oil, are sent to storage tanks.

When loading to a ship, the products (crude, naphtha, butane or propane) are pumped along the 2.4 km jetty then conveyed through hydraulically controlled loading arms into the ship tanks for transport to Australian refineries or overseas.

South West Queensland

Production is based around Ballera, Queensland, where a production facility to condition the gas for transport was established in 1993. Gas is sold to markets at Mount Isa and Brisbane. Raw gas is also transported to Moomba where it is processed for markets in New South Wales and South Australia.

Since January 2009, the Queensland to South Australia/New South Wales (QSN Link Pipeline) between Ballera (Qld) and Moomba (SA) has transported sales gas sourced from coal seam methane reserves in south-eastern Queensland directly into the Moomba to Adelaide Pipeline. The QSN Link is also capable of delivering directly into the Moomba to Sydney Pipeline. In 2010 Epic Energy commenced a significant expansion of the South West Queensland Pipeline which includes looping of the QSN Link Pipeline.

Otway Basin

A flowline network and processing plant gather and treat the raw gas which is produced from the gas wells of the Katnook, Haselgrove, Haselgrove South and Redman fields. Minimum processing occurs. The gas which is non-corrosive and non-toxic is cooled to separate and remove water vapour and condensate. Sales gas is sold at the outlet from the Katnook Plant and delivered to markets serviced by the South East Pipeline System. Condensate is stored onsite at the Katnook Plant before transportation by road tanker to the Shell Refinery, Geelong, Victoria.

Natural gas from Victoria, transported via the Port Campbell to Adelaide Pipeline and the SESA Pipeline, powers the 80 MW Ladbroke Grove power station adjacent to the Katnook facility. This gas also supplies markets serviced by the South East Pipeline System, replacing declining supply from the local onshore fields.

Other services in the Cooper Basin

The northern part of South Australia is sparsely populated and relatively undeveloped due to its remoteness and harsh climate. Accommodation and support facilities are located at the Moomba Production Facility, operated by the Cooper Basin Joint Venture, and are not open to the general public. Access is by arrangement with the operator.

The existing Moomba Main Camp can accommodate 648 people, while the adjacent Contractors’ Camp can accommodate 184 people. All camps utilise the amenities of the Moomba Main Camp. The full range of support services are located at the Moomba Main Camp including logging, wireline, fraccing, cementing, transport, fuel supply, aviation (including helicopter) and emergency services. There is a sealed airstrip at the Moomba Production Facility. The strip is 1720 m long and is large enough to accept medium-sized jets.

The township of Innamincka is located 65 km NW of Moomba, and provides a hotel, general store and light-aircraft airstrip. The causeway at Innamincka provides the major crossing point for the Cooper Creek, which in times of flood is impassable by vehicle.

3rd party access

For more information on 3rd party access to infrastructure visit the Gas Market Reform Group website.